Page 50 - Module DMV20173

P. 50

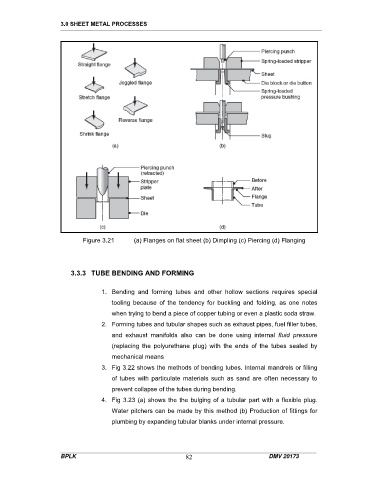

3.0 SHEET METAL PROCESSES

Figure 3.21 (a) Flanges on flat sheet (b) Dimpling (c) Piercing (d) Flanging

3.3.3 TUBE BENDING AND FORMING

1. Bending and forming tubes and other hollow sections requires special

tooling because of the tendency for buckling and folding, as one notes

when trying to bend a piece of copper tubing or even a plastic soda straw.

2. Forming tubes and tubular shapes such as exhaust pipes, fuel filler tubes,

and exhaust manifolds also can be done using internal fluid pressure

(replacing the polyurethane plug) with the ends of the tubes sealed by

mechanical means

3. Fig 3.22 shows the methods of bending tubes. Internal mandrels or filling

of tubes with particulate materials such as sand are often necessary to

prevent collapse of the tubes during bending.

4. Fig 3.23 (a) shows the the bulging of a tubular part with a flexible plug.

Water pitchers can be made by this method (b) Production of fittings for

plumbing by expanding tubular blanks under internal pressure.

BPLK 82 DMV 20173