Page 51 - Module DMV20173

P. 51

3.0 SHEET METAL PROCESSES

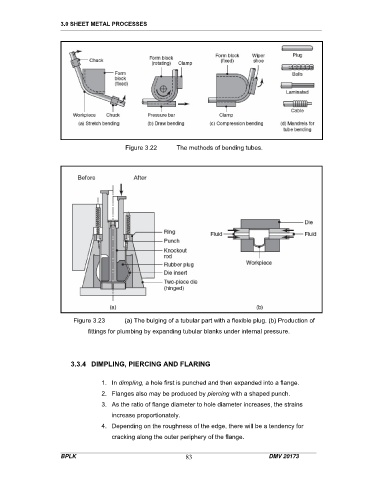

Figure 3.22 The methods of bending tubes.

Figure 3.23 (a) The bulging of a tubular part with a flexible plug. (b) Production of

fittings for plumbing by expanding tubular blanks under internal pressure.

3.3.4 DIMPLING, PIERCING AND FLARING

1. In dimpling, a hole first is punched and then expanded into a flange.

2. Flanges also may be produced by piercing with a shaped punch.

3. As the ratio of flange diameter to hole diameter increases, the strains

increase proportionately.

4. Depending on the roughness of the edge, there will be a tendency for

cracking along the outer periphery of the flange.

BPLK 83 DMV 20173