Page 57 - Module DMV20173

P. 57

3.0 SHEET METAL PROCESSES

Figure 3.28 A schematic section of a typical stamping die. The sheet contacts only the

punch or the die at any point.

3.4.1 RUBBER FORMING & HYDROFORMING

1. Rubber forming is a process of bending and embossing of sheet metal using

rubber pad (Polyurethanes) as a replacement die (as female die).

2. Polyurethanes are used widely because of their:-

a. Resistance to cutting or tearing by burrs or other sharp edges on the sheet

metal.

b. Long fatigue life.

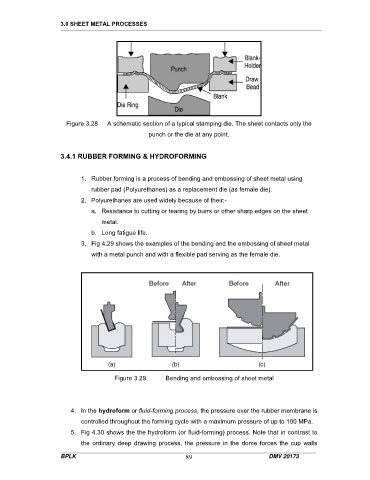

3. Fig 4.29 shows the examples of the bending and the embossing of sheet metal

with a metal punch and with a flexible pad serving as the female die.

Figure 3.29 Bending and embossing of sheet metal

4. In the hydroform or fluid-forming process, the pressure over the rubber membrane is

controlled throughout the forming cycle with a maximum pressure of up to 100 MPa.

5. Fig 4.30 shows the the hydroform (or fluid-forming) process. Note that in contrast to

the ordinary deep drawing process, the pressure in the dome forces the cup walls

BPLK 89 DMV 20173