Page 62 - Module DMV20173

P. 62

3.0 SHEET METAL PROCESSES

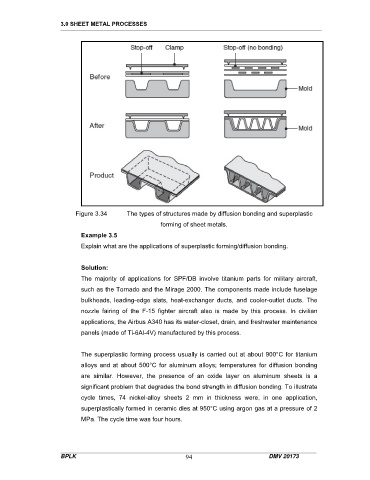

Figure 3.34 The types of structures made by diffusion bonding and superplastic

forming of sheet metals.

Example 3.5

Explain what are the applications of superplastic forming/diffusion bonding.

Solution:

The majority of applications for SPF/DB involve titanium parts for military aircraft,

such as the Tornado and the Mirage 2000. The components made include fuselage

bulkheads, leading-edge slats, heat-exchanger ducts, and cooler-outlet ducts. The

nozzle fairing of the F-15 fighter aircraft also is made by this process. In civilian

applications, the Airbus A340 has its water-closet, drain, and freshwater maintenance

panels (made of Ti-6Al-4V) manufactured by this process.

The superplastic forming process usually is carried out at about 900°C for titanium

alloys and at about 500°C for aluminum alloys; temperatures for diffusion bonding

are similar. However, the presence of an oxide layer on aluminum sheets is a

significant problem that degrades the bond strength in diffusion bonding. To illustrate

cycle times, 74 nickel-alloy sheets 2 mm in thickness were, in one application,

superplastically formed in ceramic dies at 950°C using argon gas at a pressure of 2

MPa. The cycle time was four hours.

BPLK 94 DMV 20173