Page 60 - Module DMV20173

P. 60

3.0 SHEET METAL PROCESSES

b. Shear spinning

1. Also known as power spinning, flow turning, hydrospinning, and spin forging, this

operation produces an axisymmetric conical or curvilinear shape, reducing the

sheet’s thickness while maintaining its maximum (blank) diameter.

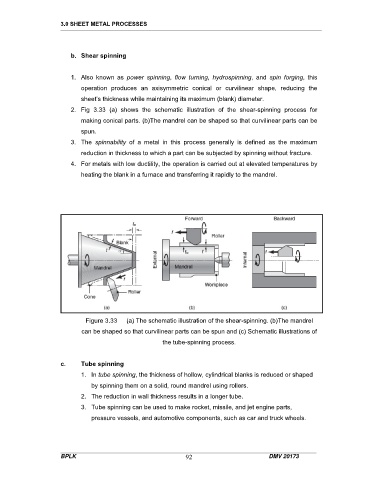

2. Fig 3.33 (a) shows the schematic illustration of the shear-spinning process for

making conical parts. (b)The mandrel can be shaped so that curvilinear parts can be

spun.

3. The spinnability of a metal in this process generally is defined as the maximum

reduction in thickness to which a part can be subjected by spinning without fracture.

4. For metals with low ductility, the operation is carried out at elevated temperatures by

heating the blank in a furnace and transferring it rapidly to the mandrel.

Figure 3.33 (a) The schematic illustration of the shear-spinning. (b)The mandrel

can be shaped so that curvilinear parts can be spun and (c) Schematic illustrations of

the tube-spinning process.

c. Tube spinning

1. In tube spinning, the thickness of hollow, cylindrical blanks is reduced or shaped

by spinning them on a solid, round mandrel using rollers.

2. The reduction in wall thickness results in a longer tube.

3. Tube spinning can be used to make rocket, missile, and jet engine parts,

pressure vessels, and automotive components, such as car and truck wheels.

BPLK 92 DMV 20173