Page 55 - 2010-2022 hose manufactureing ability and guide

P. 55

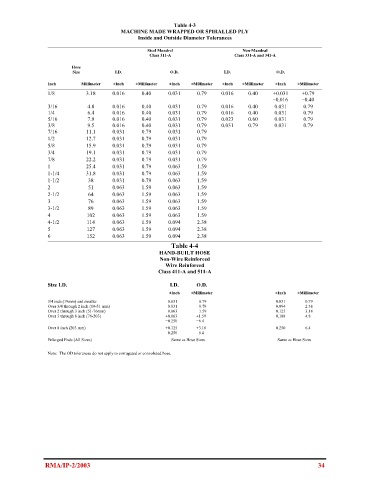

Table 4-3

MACHINE MADE WRAPPED OR SPIRALLED PLY

Inside and Outside Diameter Tolerances

Steel Mandrel Non-Mandral

Class 311-A Class 331-A and 341-A

Hose

Size I.D. O.D. I.D. O.D.

Inch Millimeter ±Inch ±Millimeter ±Inch ±Millimeter ±Inch ±Millimeter ±Inch ±Millimeter

1/8 3.18 0.016 0.40 0.031 0.79 0.016 0.40 +0.031 +0.79

−0.016 −0.40

3/16 4.8 0.016 0.40 0.031 0.79 0.016 0.40 0.031 0.79

1/4 6.4 0.016 0.40 0.031 0.79 0.016 0.40 0.031 0.79

5/16 7.9 0.016 0.40 0.031 0.79 0.023 0.60 0.031 0.79

3/8 9.5 0.016 0.40 0.031 0.79 0.031 0.79 0.031 0.79

7/16 11.1 0.031 0.79 0.031 0.79

1/2 12.7 0.031 0.79 0.031 0.79

5/8 15.9 0.031 0.79 0.031 0.79

3/4 19.1 0.031 0.79 0.031 0.79

7/8 22.2 0.031 0.79 0.031 0.79

1 25.4 0.031 0.79 0.063 1.59

1-1/4 31.8 0.031 0.79 0.063 1.59

1-1/2 38 0.031 0.79 0.063 1.59

2 51 0.063 1.59 0.063 1.59

2-1/2 64 0.063 1.59 0.063 1.59

3 76 0.063 1.59 0.063 1.59

3-1/2 89 0.063 1.59 0.063 1.59

4 102 0.063 1.59 0.063 1.59

4-1/2 114 0.063 1.59 0.094 2.38

5 127 0.063 1.59 0.094 2.38

6 152 0.063 1.59 0.094 2.38

Table 4-4

HAND-BUILT HOSE

Non-Wire Reinforced

Wire Reinforced

Class 411-A and 511-A

Size I.D. I.D. O.D.

±Inch ±Millimeter ±Inch ±Millimeter

3/4 inch (19mm) and smaller 0.031 0.79 0.031 0.79

Over 3/4 through 2 inch (19-51 mm) 0.031 0.79 0.094 2.38

Over 2 through 3 inch (51-76mm) 0.063 1.59 0.125 3.18

Over 3 through 8 inch (76-203) +0.063 +1.59 0.188 4.8

−0.250 −6.4

Over 8 inch (203 mm) +0.125 +3.18 0.250 6.4

−0.250 −6.4

Enlarged Ends (All Sizes) Same as Hose Sizes Same as Hose Sizes

Note: The OD tolerances do not apply to corrugated or convoluted hose.

RMA/IP-2/2003 34