Page 58 - 2010-2022 hose manufactureing ability and guide

P. 58

COUPLINGS

Chapter 5

CAUTION! Because the hose/coupling interface is critical to hose assembly performance,

always follow the specific instructions of hose and couplings manufacturers regarding the

match of hose/fittings and assembly procedures. Trained personnel using proper tools and

procedures should make hose assemblies. Failure to follow manufacturer's instructions or

failure to use trained personnel might be dangerous and could result in damage to property and

serious bodily injury.

The value of a hose is enhanced by the proper selection of couplings. Couplings attach to the end

of hose in order to facilitate connection to a pressure source. In order to make this transition

successful, the coupling termination must provide a leak proof seal and the hose/coupling interface

must be properly matched.

The three basic methods for making leak proof terminations are:

1. Washer seal

2. Mechanical seal

3. Thread seal

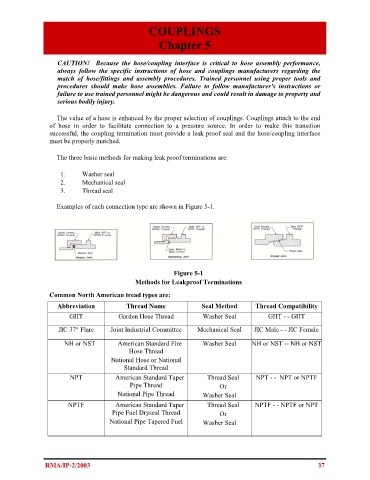

Examples of each connection type are shown in Figure 5-1.

Figure 5-1

Methods for Leakproof Terminations

Common North American tread types are:

Abbreviation Thread Name Seal Method Thread Compatibility

GHT Garden Hose Thread Washer Seal GHT - - GHT

JIC 37° Flare Joint Industrial Committee Mechanical Seal JIC Male - - JIC Female

NH or NST American Standard Fire Washer Seal NH or NST -- NH or NST

Hose Thread

National Hose or National

Standard Thread

NPT American Standard Taper Thread Seal NPT - - NPT or NPTF

Pipe Thread Or

National Pipe Thread Washer Seal

NPTF American Standard Taper Thread Seal NPTF - - NPTF or NPT

Pipe Fuel Dryseal Thread Or

National Pipe Tapered Fuel Washer Seal

RMA/IP-2/2003 37