Page 61 - 2010-2022 hose manufactureing ability and guide

P. 61

Figure 5-10. Reusable hydraulic hose

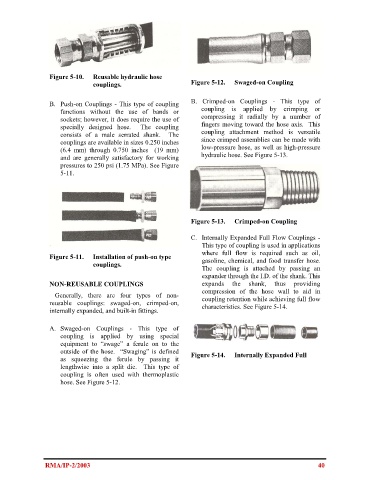

couplings. Figure 5-12. Swaged-on Coupling

B. Push-on Couplings - This type of coupling B. Crimped-on Couplings - This type of

functions without the use of bands or coupling is applied by crimping or

sockets; however, it does require the use of compressing it radially by a number of

specially designed hose. The coupling fingers moving toward the hose axis. This

consists of a male serrated shank. The coupling attachment method is versatile

couplings are available in sizes 0.250 inches since crimped assemblies can be made with

(6.4 mm) through 0.750 inches (19 mm) low-pressure hose, as well as high-pressure

and are generally satisfactory for working hydraulic hose. See Figure 5-13.

pressures to 250 psi (1.75 MPa). See Figure

5-11.

Figure 5-13. Crimped-on Coupling

C. Internally Expanded Full Flow Couplings -

This type of coupling is used in applications

where full flow is required such as oil,

Figure 5-11. Installation of push-on type

couplings. gasoline, chemical, and food transfer hose.

The coupling is attached by passing an

expander through the I.D. of the shank. This

NON-REUSABLE COUPLINGS expands the shank, thus providing

compression of the hose wall to aid in

Generally, there are four types of non-

reusable couplings: swaged-on, crimped-on, coupling retention while achieving full flow

internally expanded, and built-in fittings. characteristics. See Figure 5-14.

A. Swaged-on Couplings - This type of

coupling is applied by using special

equipment to “swage” a ferule on to the

outside of the hose. “Swaging” is defined Figure 5-14. Internally Expanded Full

as squeezing the ferule by passing it

lengthwise into a split die. This type of

coupling is often used with thermoplastic

hose. See Figure 5-12.

RMA/IP-2/2003 40