Page 63 - 2010-2022 hose manufactureing ability and guide

P. 63

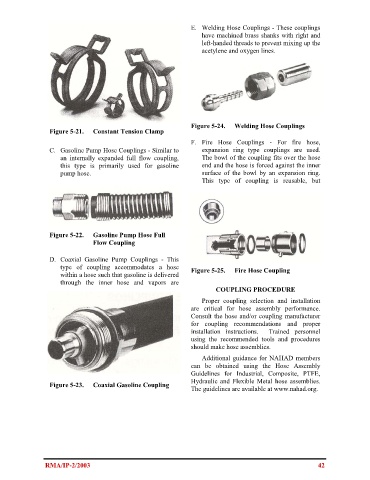

E. Welding Hose Couplings - These couplings

have machined brass shanks with right and

left-handed threads to prevent mixing up the

acetylene and oxygen lines.

Figure 5-24. Welding Hose Couplings

Figure 5-21. Constant Tension Clamp

F. Fire Hose Couplings - For fire hose,

C. Gasoline Pump Hose Couplings - Similar to expansion ring type couplings are used.

an internally expanded full flow coupling, The bowl of the coupling fits over the hose

this type is primarily used for gasoline end and the hose is forced against the inner

pump hose. surface of the bowl by an expansion ring.

This type of coupling is reusable, but

Figure 5-22. Gasoline Pump Hose Full

Flow Coupling

D. Coaxial Gasoline Pump Couplings - This

type of coupling accommodates a hose Figure 5-25. Fire Hose Coupling

within a hose such that gasoline is delivered

through the inner hose and vapors are

COUPLING PROCEDURE

Proper coupling selection and installation

are critical for hose assembly performance.

Consult the hose and/or coupling manufacturer

for coupling recommendations and proper

installation instructions. Trained personnel

using the recommended tools and procedures

should make hose assemblies.

Additional guidance for NAHAD members

can be obtained using the Hose Assembly

Guidelines for Industrial, Composite, PTFE,

Hydraulic and Flexible Metal hose assemblies.

Figure 5-23. Coaxial Gasoline Coupling

The guidelines are available at www.nahad.org.

RMA/IP-2/2003 42