Page 62 - 2010-2022 hose manufactureing ability and guide

P. 62

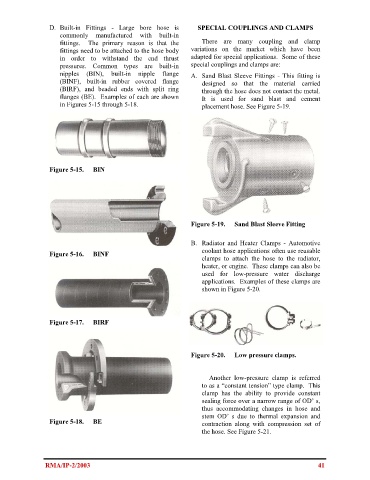

D. Built-in Fittings - Large bore hose is SPECIAL COUPLINGS AND CLAMPS

commonly manufactured with built-in

fittings. The primary reason is that the There are many coupling and clamp

fittings need to be attached to the hose body variations on the market which have been

in order to withstand the end thrust adapted for special applications. Some of these

pressures. Common types are built-in special couplings and clamps are:

nipples (BIN), built-in nipple flange A. Sand Blast Sleeve Fittings - This fitting is

(BINF), built-in rubber covered flange designed so that the material carried

(BIRF), and beaded ends with split ring through the hose does not contact the metal.

flanges (BE). Examples of each are shown It is used for sand blast and cement

in Figures 5-15 through 5-18. placement hose. See Figure 5-19.

Figure 5-15. BIN

Figure 5-19. Sand Blast Sleeve Fitting

B. Radiator and Heater Clamps - Automotive

coolant hose applications often use reusable

Figure 5-16. BINF

clamps to attach the hose to the radiator,

heater, or engine. These clamps can also be

used for low-pressure water discharge

applications. Examples of these clamps are

shown in Figure 5-20.

Figure 5-17. BIRF

Figure 5-20. Low pressure clamps.

Another low-pressure clamp is referred

to as a “constant tension” type clamp. This

clamp has the ability to provide constant

sealing force over a narrow range of OD’ s,

thus accommodating changes in hose and

stem OD’ s due to thermal expansion and

Figure 5-18. BE contraction along with compression set of

the hose. See Figure 5-21.

RMA/IP-2/2003 41