Page 351 - Basic Principles of Textile Coloration

P. 351

340 REACTIVE DYES

sensitivity to bleaching by chlorine of some reactive dyes, over-chlorinated water

must be avoided or treated with a reducing agent such as sodium bisulphite or

thiosulphate.

16.3.2 The three-step exhaust dyeing process

A typical exhaust dyeing process for cellulosic materials using reactive dyes has

three distinct phases:

(1) the initial exhaustion phase. Dyeing is started in neutral solution so that

there is little likelihood of the dye reacting with the cellulose. During this

stage of dyeing, some reactive dye will be absorbed by the fibres, the amount

depending upon its substantivity. This dye is capable of migration to promote

level dyeing. Sodium chloride or sulphate will often be present initially or be

added gradually to the dyebath during this phase to promote exhaustion. The

temperature of the dyebath may also be gradually increased to aid penetration

of dye into the fibres and to assist migration;

(2) the fixation phase. After the initial exhaustion phase, the pH of the dyebath

is increased by complete or gradual addition of the appropriate type and

amount of alkali. This causes dissociation of some of the hydroxyl groups in

the cellulose and the nucleophilic cellulosate ions begin to react with the dye.

The fixation process then results in additional dye absorption, to re-establish

the dyeing equilibrium. Dye absorption from solution and reaction with the

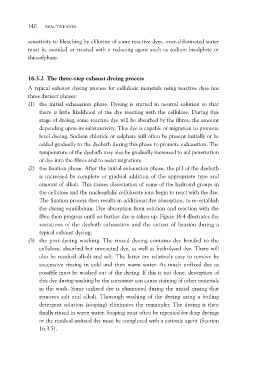

fibre then progress until no further dye is taken up. Figure 16.4 illustrates the

variations of the dyebath exhaustion and the extent of fixation during a

typical exhaust dyeing;

(3) the post-dyeing washing. The rinsed dyeing contains dye bonded to the

cellulose, absorbed but unreacted dye, as well as hydrolysed dye. There will

also be residual alkali and salt. The latter are relatively easy to remove by

successive rinsing in cold and then warm water. As much unfixed dye as

possible must be washed out of the dyeing. If this is not done, desorption of

this dye during washing by the consumer can cause staining of other materials

in the wash. Some unfixed dye is eliminated during the initial rinsing that

removes salt and alkali. Thorough washing of the dyeing using a boiling

detergent solution (soaping) eliminates the remainder. The dyeing is then

finally rinsed in warm water. Soaping must often be repeated for deep dyeings

or the residual unfixed dye must be complexed with a cationic agent (Section

16.3.5).