Page 82 - Lecture Notes DCC3113

P. 82

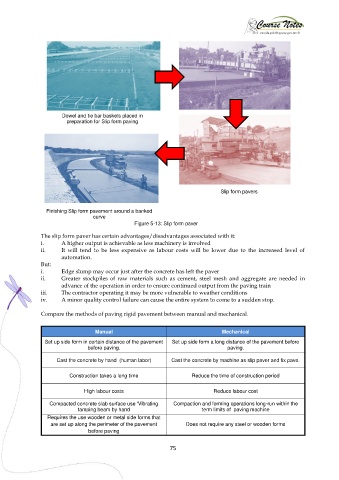

Dowel and tie bar baskets placed in

preparation for Slip form paving

Slip form pavers

Finishing Slip form pavement around a banked

curve

Figure 5-13: Slip form paver

Work

The slip form paver has certain advantages/disadvantages associated with it:

i. A higher output is achievable as less machinery is involved

ii. It will tend to be less expensive as labour costs will be lower due to the increased level of

automation.

But:

i. Edge slump may occur just after the concrete has left the paver

ii. Greater stockpiles of raw materials such as cement, steel mesh and aggregate are needed in

advance of the operation in order to ensure continued output from the paving train

iii. The contractor operating it may be more vulnerable to weather conditions

iv. A minor quality control failure can cause the entire system to come to a sudden stop.

Compare the methods of paving rigid pavement between manual and mechanical.

Manual Mechanical

Set up side form in certain distance of the pavement Set up side form a long distance of the pavement before

before paving. paving.

Cast the concrete by hand (human labor) Cast the concrete by machine as slip paver and fix pave.

Construction takes a long time Reduce the time of construction period

High labour costs Reduce labour cost

Compacted concrete slab surface use 'Vibrating Compaction and forming operations long-run within the

tamping beam by hand term limits of paving machine

Requires the use wooden or metal side forms that

are set up along the perimeter of the pavement Does not require any steel or wooden forms

before paving

75