Page 13 - i-MeIV Product Information

P. 13

EV System

2-2-1 Electric Motor [for driving]

i MiEV uses a compact, high-performance, permanent magnet synchronous type electrical motor instead of an engine.

This motor can deliver the maximum torque even from 0 [r/min] .

This motor requires AC 330V therefore, DC 330V at battery pack is transform to AC 330V by inverter.

Unlike internal combustion engine vehicles, it can cover the entire range of driving speed without any

transmission system. It also helps to reduce the vehicle weight.

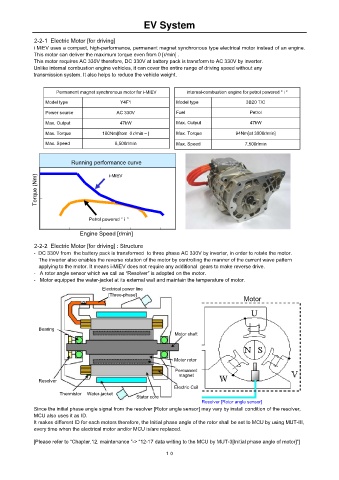

Permanent magnet synchronous motor for i-MiEV internal-combustion engine for petrol powered “ i “

Model type Y4F1 Model type 3B20 T/C

Power source AC 330V Fuel Petrol

Max. Output 47kW Max. Output 47kW

Max. Torque 180Nm[from 0r/min~] Max. Torque 94Nm[at 3000r/min]

Max. Speed 8,500r/min Max. Speed 7,500r/min

Running performance curve

Torque (Nm)

i-MiEV

Petrol powered “i”

Engine Speed [r/min]

2-2-2 Electric Motor [for driving] : Structure

- DC 330V from the battery pack is transformed to three phase AC 330V by inverter, in order to rotate the motor.

The inverter also enables the reverse rotation of the motor by controlling the manner of the current wave pattern

applying to the motor. It means i-MiEV does not require any additional gears to make reverse drive.

- A rotor angle sensor which we call as “Resolver” is adopted on the motor.

- Motor equipped the water-jacket at its external wall and maintain the temperature of motor.

Electrical power line

[Three-phase]

Motor

Bearing

Motor shaft

Motor rotor

Permanent

magnet

Resolver

Electric Coil

Thermistor Water-jacket

Stator core

Resolver [Rotor angle sensor]

Since the initial phase angle signal from the resolver [Rotor angle sensor] may vary by install condition of the resolver,

MCU also uses it as ID.

It makes different ID for each motors therefore, the Initial phase angle of the rotor shall be set to MCU by using MUT-III,

every time when the electrical motor and/or MCU is/are replaced.

[Please refer to “Chapter.12. maintenance “-> “12-17 data writing to the MCU by MUT-3[Initial phase angle of motor]”]

10