Page 5 - E BOOK ENGINE MECHANICAL M2

P. 5

1. TECHNICAL FEATURES OF 4B1 ENGINE

2. FEATURES OF COMPOSING PARTS

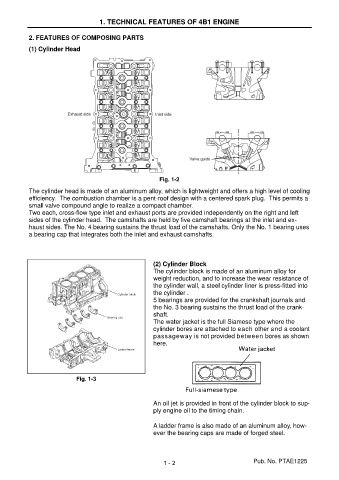

(1) Cylinder Head

Fig. 1-2

The cylinder head is made of an aluminum alloy, which is lightweight and offers a high level of cooling

efficiency. The combustion chamber is a pent-roof design with a centered spark plug. This permits a

small valve compound angle to realize a compact chamber.

Two each, cross-flow type inlet and exhaust ports are provided independently on the right and left

sides of the cylinder head. The camshafts are held by five camshaft bearings at the inlet and ex-

haust sides. The No. 4 bearing sustains the thrust load of the camshafts. Only the No. 1 bearing uses

a bearing cap that integrates both the inlet and exhaust camshafts.

(2) Cylinder Block

The cylinder block is made of an aluminum alloy for

weight reduction, and to increase the wear resistance of

the cylinder wall, a steel cylinder liner is press-fitted into

the cylinder .

5 bearings are provided for the crankshaft journals and

the No. 3 bearing sustains the thrust load of the crank-

shaft.

The water jacket is the full Siamese type where the

cylinder bores are attached to each other and a coolant

passageway is not provided between bores as shown

here.

Fig. 1-3

An oil jet is provided in front of the cylinder block to sup-

ply engine oil to the timing chain.

A ladder frame is also made of an aluminum alloy, how-

ever the bearing caps are made of forged steel.

1 - 2 Pub. No. PTAE1225