Page 9 - E BOOK ENGINE MECHANICAL M2

P. 9

1. TECHNICAL FEATURES OF 4B1 ENGINE

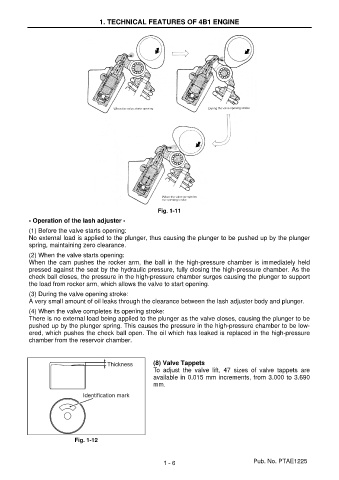

Fig. 1-11

- Operation of the lash adjuster -

(1) Before the valve starts opening:

No external load is applied to the plunger, thus causing the plunger to be pushed up by the plunger

spring, maintaining zero clearance.

(2) When the valve starts opening:

When the cam pushes the rocker arm, the ball in the high-pressure chamber is immediately held

pressed against the seat by the hydraulic pressure, fully closing the high-pressure chamber. As the

check ball closes, the pressure in the high-pressure chamber surges causing the plunger to support

the load from rocker arm, which allows the valve to start opening.

(3) During the valve opening stroke:

A very small amount of oil leaks through the clearance between the lash adjuster body and plunger.

(4) When the valve completes its opening stroke:

There is no external load being applied to the plunger as the valve closes, causing the plunger to be

pushed up by the plunger spring. This causes the pressure in the high-pressure chamber to be low-

ered, which pushes the check ball open. The oil which has leaked is replaced in the high-pressure

chamber from the reservoir chamber.

(8) Valve Tappets

To adjust the valve lift, 47 sizes of valve tappets are

available in 0.015 mm increments, from 3.000 to 3.690

mm.

Fig. 1-12

1 - 6 Pub. No. PTAE1225