Page 74 - E BOOK ENGINE MECHANICAL M2

P. 74

4. SERVICE POINTS OF 4D56 ENGINE COMPONENT

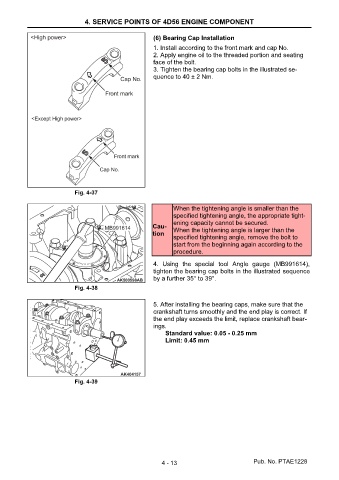

(6) Bearing Cap Installation

1. Install according to the front mark and cap No.

2. Apply engine oil to the threaded portion and seating

face of the bolt.

3. Tighten the bearing cap bolts in the illustrated se-

quence to 40 ± 2 Nm.

Fig. 4-37

When the tightening angle is smaller than the

specified tightening angle, the appropriate tight-

ening capacity cannot be secured.

Cau- When the tightening angle is larger than the

tion

specified tightening angle, remove the bolt to

start from the beginning again according to the

procedure.

4. Using the special tool Angle gauge (MB991614),

tighten the bearing cap bolts in the illustrated sequence

by a further 35° to 39°.

Fig. 4-38

5. After installing the bearing caps, make sure that the

crankshaft turns smoothly and the end play is correct. If

the end play exceeds the limit, replace crankshaft bear-

ings.

Standard value: 0.05 - 0.25 mm

Limit: 0.45 mm

Fig. 4-39

4 - 13 Pub. No. PTAE1228