Page 72 - E BOOK ENGINE MECHANICAL M2

P. 72

4. SERVICE POINTS OF 4D56 ENGINE COMPONENT

6. Using the special tool Angle gauge (MB991614),

tighten the connecting rod cap nut in the illustrated se-

quence by a further 90° to 94°.

When the tightening angle is smaller than the

specified tightening angle, the appropriate tighten-

Cau- ing capacity cannot be secured.

tion When the tightening angle is larger than the speci-

fied tightening angle, remove the bolt to start from

the beginning again according to the procedure.

Fig. 4-32

7. Make sure that connecting rod big end side clearance

meets the specification.

Standard value: 0.10 - 0.25 mm

Limit: 0.40 mm

Fig. 4-33

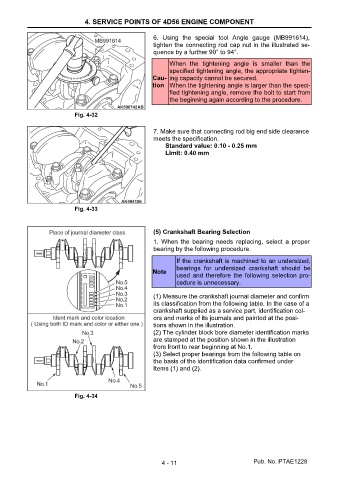

(5) Crankshaft Bearing Selection

1. When the bearing needs replacing, select a proper

bearing by the following procedure.

If the crankshaft is machined to an undersized,

bearings for undersized crankshaft should be

Note

used and therefore the following selection pro-

cedure is unnecessary.

(1) Measure the crankshaft journal diameter and confirm

its classification from the following table. In the case of a

crankshaft supplied as a service part, identification col-

ors and marks of its journals and painted at the posi-

tions shown in the illustration.

(2) The cylinder block bore diameter identification marks

are stamped at the position shown in the illustration

from front to rear beginning at No.1.

(3) Select proper bearings from the following table on

the basis of the identification data confirmed under

Items (1) and (2).

Fig. 4-34

4 - 11 Pub. No. PTAE1228