Page 70 - E BOOK ENGINE MECHANICAL M2

P. 70

4. SERVICE POINTS OF 4D56 ENGINE COMPONENT

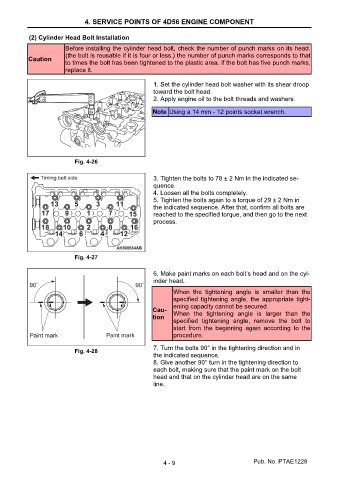

(2) Cylinder Head Bolt Installation

Before installing the cylinder head bolt, check the number of punch marks on its head.

(the bolt is reusable if it is four or less.) the number of punch marks corresponds to that

Caution

to times the bolt has been tightened to the plastic area. if the bolt has five punch marks,

replace it.

1. Set the cylinder head bolt washer with its shear droop

toward the bolt head.

2. Apply engine oil to the bolt threads and washers.

Note Using a 14 mm - 12 points socket wrench.

Fig. 4-26

3. Tighten the bolts to 78 ± 2 Nm in the indicated se-

quence.

4. Loosen all the bolts completely.

5. Tighten the bolts again to a torque of 29 ± 2 Nm in

the indicated sequence. After that, confirm all bolts are

reached to the specified torque, and then go to the next

process.

Fig. 4-27

6. Make paint marks on each bolt’s head and on the cyl-

inder head.

When the tightening angle is smaller than the

specified tightening angle, the appropriate tight-

ening capacity cannot be secured.

Cau-

tion When the tightening angle is larger than the

specified tightening angle, remove the bolt to

start from the beginning again according to the

procedure.

7. Turn the bolts 90° in the tightening direction and in

Fig. 4-28

the indicated sequence.

8. Give another 90° turn in the tightening direction to

each bolt, making sure that the paint mark on the bolt

head and that on the cylinder head are on the same

line.

4 - 9 Pub. No. PTAE1228