Page 71 - E BOOK ENGINE MECHANICAL M2

P. 71

4. SERVICE POINTS OF 4D56 ENGINE COMPONENT

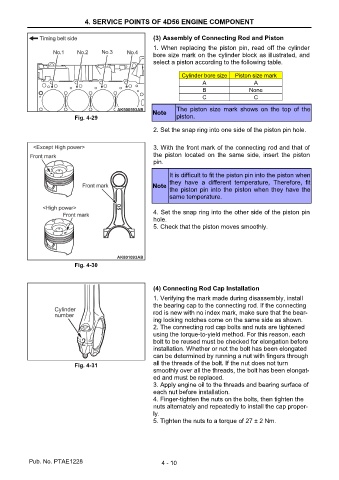

(3) Assembly of Connecting Rod and Piston

1. When replacing the piston pin, read off the cylinder

bore size mark on the cylinder block as illustrated, and

select a piston according to the following table.

Cylinder bore size Piston size mark

A A

B None

C C

The piston size mark shows on the top of the

Note

Fig. 4-29 piston.

2. Set the snap ring into one side of the piston pin hole.

3. With the front mark of the connecting rod and that of

the piston located on the same side, insert the piston

pin.

It is difficult to fit the piston pin into the piston when

they have a different temperature, Therefore, fit

Note

the piston pin into the piston when they have the

same temperature.

4. Set the snap ring into the other side of the piston pin

hole.

5. Check that the piston moves smoothly.

Fig. 4-30

(4) Connecting Rod Cap Installation

1. Verifying the mark made during disassembly, install

the bearing cap to the connecting rod. If the connecting

rod is new with no index mark, make sure that the bear-

ing locking notches come on the same side as shown.

2. The connecting rod cap bolts and nuts are tightened

using the torque-to-yield method. For this reason, each

bolt to be reused must be checked for elongation before

installation. Whether or not the bolt has been elongated

can be determined by running a nut with fingers through

Fig. 4-31 all the threads of the bolt. If the nut does not turn

smoothly over all the threads, the bolt has been elongat-

ed and must be replaced.

3. Apply engine oil to the threads and bearing surface of

each nut before installation.

4. Finger-tighten the nuts on the bolts, then tighten the

nuts alternately and repeatedly to install the cap proper-

ly.

5. Tighten the nuts to a torque of 27 ± 2 Nm.

Pub. No. PTAE1228 4 - 10