Page 47 - Arebian

P. 47

47

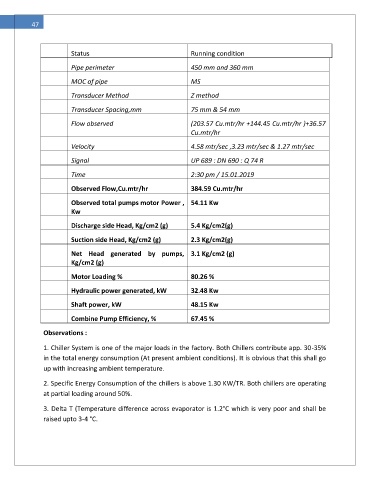

Status Running condition

Pipe perimeter 450 mm and 360 mm

MOC of pipe MS

Transducer Method Z method

Transducer Spacing,mm 75 mm & 54 mm

Flow observed (203.57 Cu.mtr/hr +144.45 Cu.mtr/hr )+36.57

Cu.mtr/hr

Velocity 4.58 mtr/sec ,3.23 mtr/sec & 1.27 mtr/sec

Signal UP 689 : DN 690 : Q 74 R

Time 2:30 pm / 15.01.2019

Observed Flow,Cu.mtr/hr 384.59 Cu.mtr/hr

Observed total pumps motor Power , 54.11 Kw

Kw

Discharge side Head, Kg/cm2 (g) 5.4 Kg/cm2(g)

Suction side Head, Kg/cm2 (g) 2.3 Kg/cm2(g)

Net Head generated by pumps, 3.1 Kg/cm2 (g)

Kg/cm2 (g)

Motor Loading % 80.26 %

Hydraulic power generated, kW 32.48 Kw

Shaft power, kW 48.15 Kw

Combine Pump Efficiency, % 67.45 %

Observations :

1. Chiller System is one of the major loads in the factory. Both Chillers contribute app. 30-35%

in the total energy consumption (At present ambient conditions). It is obvious that this shall go

up with increasing ambient temperature.

2. Specific Energy Consumption of the chillers is above 1.30 KW/TR. Both chillers are operating

at partial loading around 50%.

3. Delta T (Temperature difference across evaporator is 1.2°C which is very poor and shall be

raised upto 3-4 °C.