Page 22 - MGPI_Case_Study

P. 22

5.1.3.2.2 Training

The CSB also examined Harcros’ training program and determined

that it was deficient in effectively communicating the importance

of the critical safety steps that did not align with work practices

on the day of the incident. As part of its training program, Harcros

requires drivers to complete various tasks included on a tanker

training log; the driver’s trainer must observe and initial that

they have been completed. Two of these tasks include ensuring

“customer’s piping is to the correct storage vessel” and “constant

monitoring of the connections and tanker during the unloading

process to abate leaks or any other malfunction that might

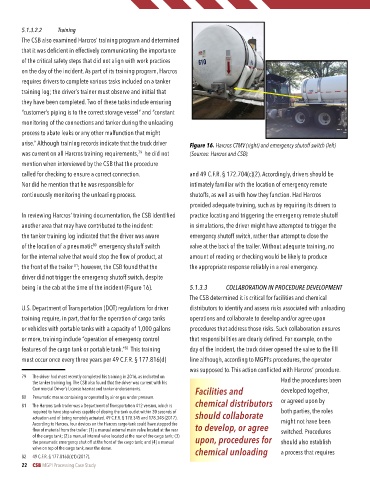

arise.” Although training records indicate that the truck driver Figure 16. Harcros CTMV (right) and emergency shutoff switch (left)

79

was current on all Harcros training requirements, he did not (Sources: Harcros and CSB).

mention when interviewed by the CSB that the procedure

called for checking to ensure a correct connection. and 49 C.F.R. § 172.704(c)(2). Accordingly, drivers should be

Nor did he mention that he was responsible for intimately familiar with the location of emergency remote

continuously monitoring the unloading process. shutoffs, as well as with how they function. Had Harcros

provided adequate training, such as by requiring its drivers to

In reviewing Harcros’ training documentation, the CSB identified practice locating and triggering the emergency remote shutoff

another area that may have contributed to the incident: in simulations, the driver might have attempted to trigger the

the tanker training log indicated that the driver was aware emergency shutoff switch, rather than attempt to close the

80

of the location of a pneumatic emergency shutoff switch valve at the back of the trailer. Without adequate training, no

for the internal valve that would stop the flow of product, at amount of reading or checking would be likely to produce

the front of the trailer ; however, the CSB found that the the appropriate response reliably in a real emergency.

81

driver did not trigger the emergency shutoff switch, despite

being in the cab at the time of the incident (Figure 16). 5.1.3.3 COLLABORATION IN PROCEDURE DEVELOPMENT

The CSB determined it is critical for facilities and chemical

U.S. Department of Transportation (DOT) regulations for driver distributors to identify and assess risks associated with unloading

training require, in part, that for the operation of cargo tanks operations and collaborate to develop and/or agree upon

or vehicles with portable tanks with a capacity of 1,000 gallons procedures that address those risks. Such collaboration ensures

or more, training include “operation of emergency control that responsibilities are clearly defined. For example, on the

features of the cargo tank or portable tank.” This training day of the incident, the truck driver opened the valve to the fill

82

must occur once every three years per 49 C.F.R. § 177.816(d) line although, according to MGPI’s procedures, the operator

was supposed to. This action conflicted with Harcros’ procedure.

79 The driver had most recently completed his training in 2016, as indicated on

the tanker training log. The CSB also found that the driver was current with his Had the procedures been

Facilities and developed together,

Commercial Driver’s License hazmat and tanker endorsements.

80 Pneumatic means containing or operated by air or gas under pressure. or agreed upon by

81 The Harcros tank trailer was a Department of Transportation 412 version, which is chemical distributors

required to have stop valves capable of closing the tank outlet within 30 seconds of should collaborate both parties, the roles

actuation and of being remotely actuated. 49 C.F.R. § 178.345 and 178.348 (2017).

According to Harcros, four devices on the Harcros cargo tank could have stopped the to develop, or agree might not have been

flow of material from the trailer: (1) a manual external main valve located at the rear switched. Procedures

of the cargo tank; (2) a manual internal valve located at the rear of the cargo tank; (3) upon, procedures for

the pneumatic emergency shut off at the front of the cargo tank; and (4) a manual should also establish

valve on top of the cargo tank, near the dome. chemical unloading

82 49 C.F.R. § 177.816(b)(1) (2017). a process that requires

22 CSB MGPI Processing Case Study