Page 7 - MGPI_Case_Study

P. 7

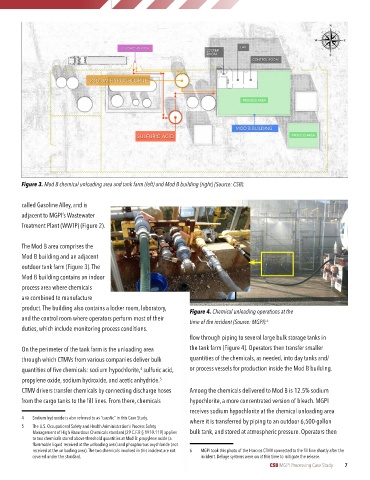

Figure 3. Mod B chemical unloading area and tank farm (left) and Mod B building (right) (Source: CSB).

called Gasoline Alley, and is

adjacent to MGPI’s Wastewater

Treatment Plant (WWTP) (Figure 2).

The Mod B area comprises the

Mod B building and an adjacent

outdoor tank farm (Figure 3). The

Mod B building contains an indoor

process area where chemicals

are combined to manufacture

product. The building also contains a locker room, laboratory,

Figure 4. Chemical unloading operations at the

and the control room where operators perform most of their

time of the incident (Source: MGPI). 6

duties, which include monitoring process conditions.

flow through piping to several large bulk storage tanks in

On the perimeter of the tank farm is the unloading area the tank farm (Figure 4). Operators then transfer smaller

through which CTMVs from various companies deliver bulk quantities of the chemicals, as needed, into day tanks and/

4

quantities of five chemicals: sodium hypochlorite, sulfuric acid, or process vessels for production inside the Mod B building.

5

propylene oxide, sodium hydroxide, and acetic anhydride.

CTMV drivers transfer chemicals by connecting discharge hoses Among the chemicals delivered to Mod B is 12.5% sodium

from the cargo tanks to the fill lines. From there, chemicals hypochlorite, a more concentrated version of bleach. MGPI

receives sodium hypochlorite at the chemical unloading area

4 Sodium hydroxide is also referred to as “caustic” in this Case Study.

where it is transferred by piping to an outdoor 6,500-gallon

5 The U.S. Occupational Safety and Health Administration’s Process Safety

Management of High Hazardous Chemicals standard (29 C.F.R § 1910.119) applies bulk tank, and stored at atmospheric pressure. Operators then

to two chemicals stored above threshold quantities at Mod B: propylene oxide (a

flammable liquid received at the unloading area) and phosphorous oxychloride (not

received at the unloading area). The two chemicals involved in this incident are not 6 MGPI took this photo of the Harcros CTMV connected to the fill line shortly after the

covered under the standard. incident. Deluge systems were on at this time to mitigate the release.

CSB MGPI Processing Case Study 7