Page 1418 - YG 2019

P. 1418

ROTARY ROTARY

TOOL HOLDERS TOOL HOLDERS

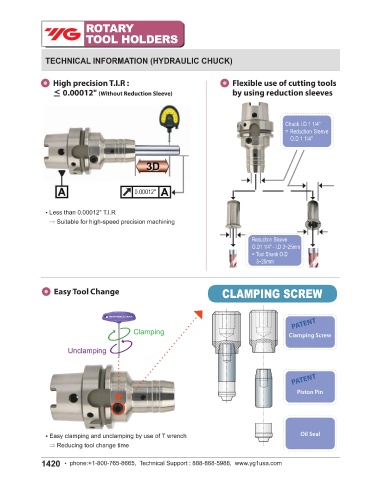

TECHNICAL INFORMATION (HYDRAULIC CHUCK) TECHNICAL INFORMATION (HYDRAULIC CHUCK)

High precision T.I.R : Flexible use of cutting tools Strong Torque Power

0.00012" (Without Reduction Sleeve) by using reduction sleeves

Minimum

Clamping Min. Torque

Hydraulic Tool Shank Applicable Power (Nm)

Chuck Depth (mm)

I.D(mm) O.D(mm) RPM

Chuck I.D 1 1/4" Slim Power Slim Power

= Reduction Sleeve E Hydro E Hydro

O.D 1 1/4" 6 6 40,000 27 16

8 8 40,000 27 23

10 10 40,000 32 45

12 12 40,000 27 41 90 110 • Tool Holder I.D Tolerance : H6

14 14 40,000 37 110 • Operating Temperature : 20~25℃

16 16 40,000 42 185 • Maximum pressure of coolant oil

18 18 40,000 42 240

0.00012" 20 20 40,000 42 48 330 520 : 80bar

25 25 25,000 48 400

• Less than 0.00012" T.I.R 32 32 25,000 55 57 650 900

⇒ Suitable for high-speed precision machining

Removing air and gas

from hydraulic oil

Reduction Sleeve Maintaining strong

O.D1 1/4" - I.D 3~25mm Vacuum Filling Filling 100% pure and stable

= Tool Shank O.D System hydraulic oil torque power

3~25mm

Test of Torque Power and Hydraulic Oil Leakage

Easy Tool Change CLAMPING SCREW

500

490 Sample1

PATENT 480 Sample2

Clamping Clamping Screw 470 Sample3

460 Sample4

Unclamping Torque Power (Nm) 450 Sample5

Sample6

440

Sample7

430 Sample8

PATENT 420 Sample9

Piston Pin 410 Sample10

400

1day 5days 10days 15days 30days

Test Duration

• Easy clamping and unclamping by use of T wrench Oil Seal • Test Model : BT40AD/B-HC20-90

⇒ Reducing tool change time • No oil leakage for long period ⇒ Maintaining stable torque power

1420 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1421