Page 863 - YG 2019

P. 863

X-POWER X-POWER

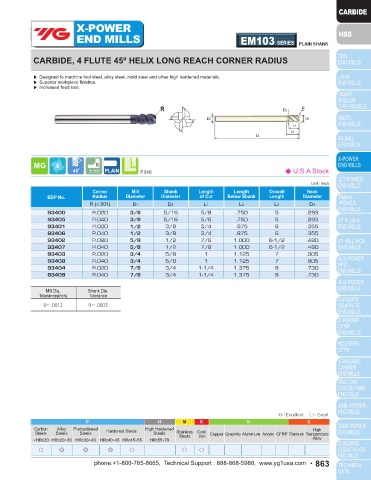

END MILLS EM102 SERIES PLAIN SHANK END MILLS EM103 SERIES PLAIN SHANK

CARBIDE, 4 FLUTE 45º HELIX LONG LENGTH CARBIDE, 4 FLUTE 45º HELIX LONG REACH CORNER RADIUS

▶ Designed to machine tool steel, alloy steel, mold steel and other high hardened materials. ▶ Designed to machine tool steel, alloy steel, mold steel and other high hardened materials.

▶ 4 flute allows for better workpiece finishes. ▶ Superior workpiece finishes.

▶ Increased production. ▶ Increased feed rate.

R D3 R

↙

D2 D1

L1

L3

L2

P.915 ◆ U.S.A Stock P.916 ◆ U.S.A Stock

Unit : Inch Unit : Inch

Length

Shank

Mill

Shank

Mill

Neck

EDP No. Diameter Diameter Length Overall EDP No. Corner Diameter Diameter Length Below Shank Overall Diameter

of Cut

Radius

Length

Length

of Cut

93395 3/8 5/16 5/8 5 R (±.001) D1 D2 L1 L3 L2 D3

93396 1/2 3/8 3/4 6 93400 R.020 3/8 5/16 5/8 .750 5 .293

93397 5/8 1/2 7/8 6-1/2 93405 R.040 3/8 5/16 5/8 .750 5 .293

93398 3/4 5/8 1 7 93401 R.020 1/2 3/8 3/4 .875 6 .355

93399 7/8 3/4 1-1/4 8 93406 R.040 1/2 3/8 3/4 .875 6 .355

93402 R.020 5/8 1/2 7/8 1.000 6-1/2 .480

Mill Dia. Shank Dia. 93407 R.040 5/8 1/2 7/8 1.000 6-1/2 .480

Tolerance(inch) Tolerance 93403 R.020 3/4 5/8 1 1.125 7 .605

93408 R.040 3/4 5/8 1 1.125 7 .605

0~-.0012 0~-.0003

93404 R.020 7/8 3/4 1-1/4 1.375 8 .730

93409 R.040 7/8 3/4 1-1/4 1.375 8 .730

Mill Dia. Shank Dia.

Enforced cutting edge Tolerance(inch) Tolerance

0~-.0012 0~-.0003

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

Iron

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ○ ◎ ◎ ◎ ○ ○ ○

862 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 863