Page 156 - belden

P. 156

H O O K - U P A N D LE A D WIRE 156

Technical Information

Temperature Classifications

Conductor Configurations

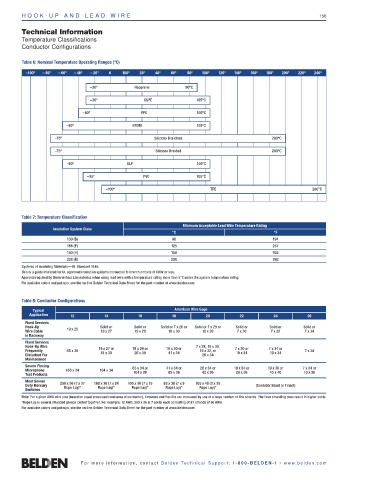

Table 6: Nominal Temperature Operating Ranges (ºC)

–100º – 80º – 60º – 40º – 20º 0 100º 20º 40º 60º 80º 100º 120º 140º 160º 180º 200º 220º 240º

–30º Neoprene 90ºC

–30º CSPE 105ºC

–40º PPO 105ºC

–60º EPDM 105ºC

–75º Silicone Braidless 200ºC

–75º Silicone Braided 200ºC

–60º XLP 105ºC

–35º PVC 105ºC

–100º TFE 260ºC

Table 7: Temperature Classification

Minimum Acceptable Lead Wire Temperature Rating

Insulation System Class

°C °F

130 (B) 90 194

155 (F) 125 257

180 (H) 150 302

220 (R) 200 392

Systems of Insulating Materials — UL Standard 1446.

This is a guide intended for UL approved insulation systems connected to branch circuits of 600V or less.

Approval required by Underwriters Laboratories when using lead wire with a temperature rating more than 5°C under the system temperature rating.

For available colors and put-ups, see the on-line Belden Technical Data Sheet for the part number at www.belden.com

Table 8: Conductor Configurations

Typical American Wire Gage

Application

12 14 16 18 20 22 24 26

Fixed Services

Hook-Up Solid or Solid or Solid or 7 x 26 or Solid or 7 x 28 or Solid or Solid or Solid or

Wire Cable 19 x 25 19 x 27 19 x 29 16 x 30 10 x 30 7 x 30 7 x 32 7 x 34

in Raceway

Fixed Services

Hook-Up Wire 7 x 28, 10 x 30,

Frequently 65 x 30 19 x 27 or 19 x 29 or 16 x 30 or 19 x 32, or 7 x 30 or 7 x 34 or 7 x 34

Disturbed For 41 x 30 26 x 30 41 x 34 26 x 34 19 x 34 10 x 34

Maintenance

Severe Flexing

Microphone 165 x 34 104 x 34 65 x 34 or 41 x 34 or 26 x 34 or 19 x 34 or 19 x 36 or 7 x 34 or

Test Products 104 x 36 65 x 36 42 x 36 26 x 36 45 x 40 10 x 36

Most Severe

Duty Mercury 259 x 36 (7 x 37 168 x 36 (7 x 24 105 x 36 (7 x 15 63 x 36 (7 x 9 105 x 40 (3 x 35 (Consider Braid or Tinsel)

Switches Rope Lay)* Rope Lay)* Rope Lay)* Rope Lay)* Rope Lay)*

Note: For a given AWG wire size (based on equal cross-sectional area of conductor), limpness and flex life are increased by use of a large number of fine strands. The finer stranding does result in higher costs.

*Rope Lay is several stranded groups cabled together. For example: 12 AWG, 259 x 36 is 7 cords each consisting of 37 strands of 36 AWG.

For available colors and put-ups, see the on-line Belden Technical Data Sheet for the part number at www.belden.com

Fo r m o r e i n fo r m at i o n, c o n t a c t Be ld e n Te ch n i ca l S u ppo r t : 1- 8 0 0 - B E L D E N -1 • www. b e l d e n . c o m