Page 53 - belden

P. 53

I N DUS T R I A L A U T O M A TI O N & P R O C E S S C O NTRO L C A B L E S 53

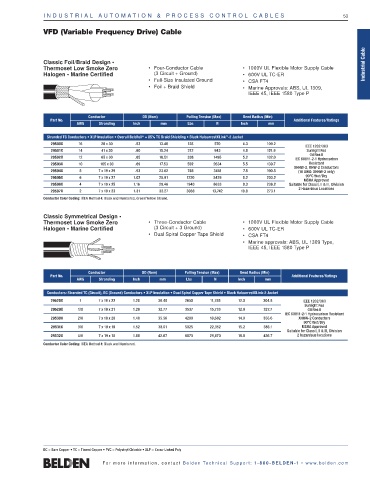

VFD (Variable Frequency Drive) Cable

Classic Foil/Braid Design • Industrial Cable

Thermoset Low Smoke Zero • Four-Conductor Cable • 1000V UL Flexible Motor Supply Cable

Halogen • Marine Certified (3 Circuit + Ground) • 600V UL TC-ER

• Full-Size Insulated Ground • CSA FT4

• Foil + Braid Shield • Marine Approvals: ABS, UL 1309,

IEEE 45, IEEE 1580 Type P

Conductor OD (Nom) Pulling Tension (Max) Bend Radius (Min)

Part No. Additional Features/Ratings

AWG Stranding Inch mm Lbs N Inch mm

Stranded TC Conductors • XLP Insulation • Overall Beldfoil ® + 85% TC Braid Shielding • Black HaloarrestXLink ™ -2 Jacket

29500X 16 26 x 30 .53 13.46 128 570 4.3 109.2

IEEE 1202/383

29501X 14 41 x 30 .60 15.24 212 943 4.8 121.9 Sunlight Res

Oil Res II

29502X 12 65 x 30 .65 16.51 336 1495 5.2 132.0 IEC 60811-2-1 Hydrocarbon

29503X 10 105 x 30 .69 17.53 592 2634 5.5 139.7 Resistant

XHHW-2, RHW-2 Conductors

29504X 8 7 x 19 x 29 .93 23.62 768 3418 7.5 190.5 (16 AWG: XHHW-2 only)

29505X 6 7 x 19 x 27 1.02 25.91 1220 5429 8.2 203.2 90°C Wet/Dry

MSHA Approved

29506X 4 7 x 19 x 25 1.16 29.46 1940 8633 9.3 236.2 Suitable for Class I, II & III, Division

2 Hazardous Locations

29507X 2 7 x 19 x 23 1.31 33.27 3088 13,742 10.8 273.1

Conductor Color Coding: ICEA Method 4: Black and Numbered, Green/Yellow Ground.

Classic Symmetrical Design •

Thermoset Low Smoke Zero • Three-Conductor Cable • 1000V UL Flexible Motor Supply Cable

Halogen • Marine Certified (3 Circuit + 3 Ground) • 600V UL TC-ER

• Dual Spiral Copper Tape Shield • CSA FT4

• Marine approvals: ABS, UL 1309 Type,

IEEE 45, IEEE 1580 Type P

Conductor OD (Nom) Pulling Tension (Max) Bend Radius (Min)

Part No. Additional Features/Ratings

AWG Stranding Inch mm Lbs N Inch mm

Conductors: Stranded TC (Circuit), BC (Ground) Conductors • XLP Insulation • Dual Spiral Copper Tape Shield • Black HaloarrestXLink-2 Jacket

29528X 1 7 x 19 x 22 1.20 30.48 2650 11,788 12.0 304.8 IEEE 1202/383

Sunlight Res

29529X 1/0 7 x 19 x 21 1.29 32.77 3537 15,733 12.9 327.7 Oil Res II

IEC 60811-2-1 Hydrocarbon Resistant

29530X 2/0 7 x 19 x 20 1.40 35.56 4200 18,682 14.0 355.6 XHHW-2 Conductors

90°C Wet/Dry

29531X 3/0 7 x 19 x 19 1.52 38.61 5025 22,352 15.2 386.1 MSHA Approved

Suitable for Class I, II & III, Division

29532X 4/0 7 x 19 x 18 1.68 42.67 6670 29,670 16.8 426.7 2 hazardous locations

Conductor Color Coding: ICEA Method 4: Black and Numbered.

BC = Bare Copper • TC = Tinned Copper • PVC = Polyvinyl Chloride • XLP = Cross-Linked Poly

Fo r m o r e i n fo r m at i o n, c o n t a c t Be ld e n Te ch n i ca l S u ppo r t : 1- 8 0 0 - B E L D E N -1 • www. b e l d e n . c o m