Page 92 - demo

P. 92

BOOK IN SERIES

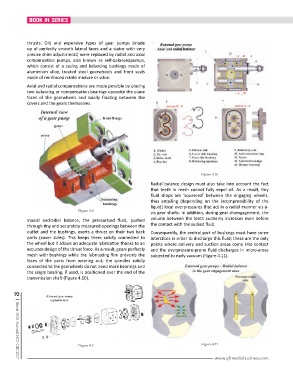

thrusts. Old and expensive types of gear pumps (made

up of perfectly smooth lateral faces and a stator with very

precise shim adjustments) were replaced by radial and axial

compensation pumps, also known as self-balancedpumps,

which consist of a casing and balancing bushings made of

aluminium alloy, treated steel gearwheels and front seals

made of reinforced nitrile mixture or viton.

Axial and radial compensations are made possible by placing

two balancing or compensation bearings opposite the plane

faces of the gearwheels and axially floating between the

covers and the gears themselves.

Figure 4.10

Radial balance design must also take into account the fact

that teeth in mesh cannot fully expel oil. As a result, tiny

fluid drops are ‘squeezed’ between the engaging wheels,

thus entailing (depending on the incompressibility of the

liquid) local overpressures that act in a radial manner vis-à-

Figure 4.8 vis gear shafts. In addition, during gear disengagement, the

Inaxial andradial balance, the pressurised fluid, pushed volume between the teeth suddenly increases even before

through tiny and accurately measured openings between the the contact with the sucked fluid.

outlet and the bushings, exerts a thrust on their two back Consequently, the central part of bushings must have some

parts (cover sides). This keeps them solidly connected to interstices in order to discharge this fluid; these are the only

the wheel but it allows an adequate lubrication thanks to an points where delivery and suction areas come into contact

accurate design of the thrust force. As a result, gears perfectly and the overpressure-prone fluid discharges in micro-areas

mesh with bushings while the lubricating film prevents the subjected to early vacuum (Figure 4.11).

faces of the parts from wearing out; the spindles solidly

connected to the gearwheels do not need more bearings and

the single bearing, if used, is positioned over the end of the

transmission shaft (Figure 4.10).

92

Figure 4.9 Figure 4.11

www.ghmediabusiness.com

| Global MDA Journal | NOV-DEC 2017