Page 90 - demo

P. 90

BOOK IN SERIES

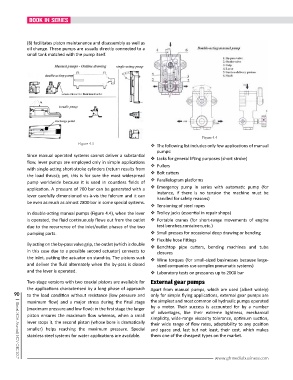

(8) facilitates piston maintenance and disassembly as well as

oil change. These pumps are usually directly connected to a

small tank matched with the pump itself.

Figure 4.4

Figure 4.3 v The following list includes only few applications of manual

pumps:

Since manual operated systems cannot deliver a substantial v Jacks for general lifting purposes (short stroke)

flow, lever pumps are employed only in simple applications

with single-acting short-stroke cylinders (return results from v Pullers

the load thrust); yet, this is for sure the most widespread v Bolt cutters

pump worldwide because it is used in countless fields of v Parallelogram platforms

application. A pressure of 700 bar can be generated with a v Emergency pump in series with automatic pump (for

lever carefully dimensioned vis-à-vis the fulcrum and it can instance, if there is no tension the machine must be

handled for safety reasons)

be even as much as almost 2800 bar in some special systems.

v Tensioning of steel ropes

In double-acting manual pumps (Figure 4.4), when the lever v Trolley jacks (essential in repair shops)

is operated, the fluid continuously flows out from the outlet v Portable cranes (for short-range movements of engine

due to the recurrence of the inlet/outlet phases of the two test benches,containers,etc.)

pumping parts. v Small presses for occasional deep drawing or bending

v Flexible hose fittings

By acting on the by-pass valve grip, the outlet (which is double v Benchtop pipe cutters, bending machines and tube

in this case due to a possible second actuator) connects to closures

the inlet, putting the actuator on stand-by. The pistons suck v Wine torques (for small-sized businesses because large-

and deliver the fluid alternately when the by-pass is closed sized companies use complex pneumatic systems)

and the lever is operated. v Laboratory tests on pressures up to 2000 bar

Two-stage versions with two coaxial pistons are available for External gear pumps

the applications characterised by a long phase of approach Apart from manual pumps, which are used (albeit widely)

90 to the load condition without resistance (low pressure and only for simple flying applications, external gear pumps are

maximum flow) and a major stress during the final stage the simplest and most common oil hydraulic pumps operated

(maximum pressure and low flow): in the first stage the larger by a motor. Their success is accounted for by a number

piston ensures the maximum flow whereas, when a small of advantages, like their extreme lightness, mechanical

simplicity, wide-range viscosity tolerance, optimum suction,

lever stops it, the second piston (whose bore is dramatically their wide range of flow rates, adaptability to any position

smaller) helps reaching the maximum pressure. Special and space and, last but not least, their cost, which makes

stainless steel systems for water applications are available. them one of the cheapest types on the market.

www.ghmediabusiness.com

| Global MDA Journal | NOV-DEC 2017