Page 602 - Ultimate Visual Dictionary (DK)

P. 602

THE MODERN WORLD

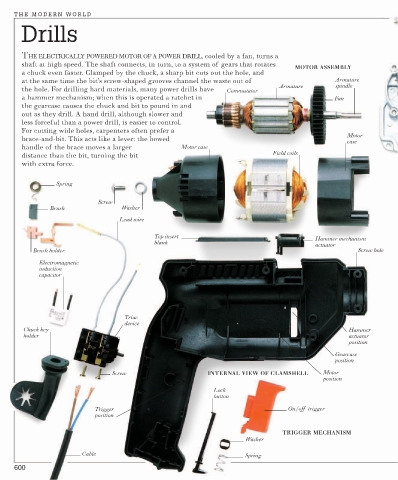

Drills

THE ELECTRICALLY POWERED MOTOR OF A POWER DRILL, cooled by a fan, turns a

shaft at high speed. The shaft connects, in turn, to a system of gears that rotates

MOTOR ASSEMBLY

a chuck even faster. Clamped by the chuck, a sharp bit cuts out the hole, and

at the same time the bit’s screw-shaped grooves channel the waste out of Armature

Armature spindle

the hole. For drilling hard materials, many power drills have Commutator

a hammer mechanism; when this is operated a ratchet in Fan

the gearcase causes the chuck and bit to pound in and

out as they drill. A hand drill, although slower and

less forceful than a power drill, is easier to control.

For cutting wide holes, carpenters often prefer a

Motor

brace-and-bit. This acts like a lever: the bowed

case

handle of the brace moves a larger Motor case

distance than the bit, turning the bit Field coils

with extra force.

Spring

Screw

Brush Washer

Lead wire

Top insert Hammer mechanism

blank

actuator

Brush holder Screw hole

Electromagnetic

induction

capacitor

Triac

device

Chuck key Hammer

holder actuator

position

Gearcase

position

Screw INTERNAL VIEW OF CLAMSHELL Motor

position

Lock

button

Trigger On/off trigger

position

TRIGGER MECHANISM

Washer

Cable Spring

600