Page 13 - REC :: M.Tech. BioTech Curriculum and Syllabus - R2019

P. 13

products).

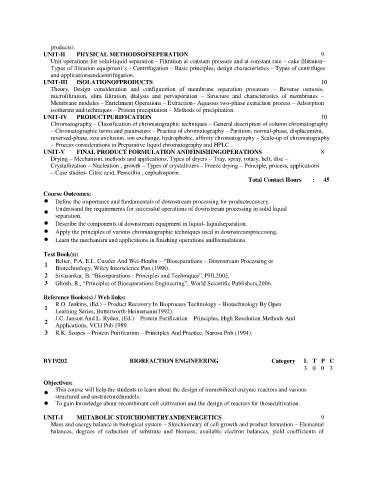

UNIT-II PHYSICAL METHODSOFSEPERATION 9

Unit operations for solid-liquid separation - Filtration at constant pressure and at constant rate – cake filtration–

Types of filtration equipment’s – Centrifugation – Basic principles, design characteristics – Types of centrifuges

and applicationsandcentrifugation.

UNIT-III ISOLATIONOFPRODUCTS 10

Theory, Design consideration and configuration of membrane separation processes – Reverse osmosis,

microfiltration, ultra filtration, dialysis and pervaporation – Structure and characteristics of membranes –

Membrane modules – Enrichment Operations – Extraction– Aqueous two-phase extraction process – Adsorption

isotherms and techniques – Protein precipitation – Methods of precipitation.

UNIT-IV PRODUCTPURIFICATION 10

Chromatography – Classification of chromatographic techniques – General description of column chromatography

– Chromatographic terms and parameters – Practice of chromatography – Partition, normal-phase, displacement,

reversed-phase, size exclusion, ion exchange, hydrophobic, affinity chromatography – Scale-up of chromatography

– Process considerations in Preparative liquid chromatography and HPLC .

UNIT-V FINAL PRODUCT FORMULATION ANDFINISHINGOPERATIONS 8

Drying – Mechanism, methods and applications, Types of dryers – Tray, spray, rotary, belt, disc –

Crystallization – Nucleation , growth – Types of crystallizers – Freeze drying – Principle, process, applications

– Case studies- Citric acid, Penicillin , cephalosporin.

Total Contact Hours : 45

Course Outcomes:

Define the importance and fundamentals of downstream processing for productrecovery.

Understand the requirements for successful operations of downstream processing in solid liquid

separation.

Describe the components of downstream equipment in liquid- liquidseparation.

Apply the principles of various chromatographic techniques used in downstreamprocessing.

Learn the mechanism and applications in finishing operations andformulations.

Text Book(s):

Belter, P.A. E.L. Cussler And Wei-Houhu – “Bioseparations – Downstream Processing or

1

Biotechnology, Wiley Interscience Pun.(1988).

2 Sivasankar, B. “Bioseparations : Principles and Techniques”. PHI,2005.

3 Ghosh, R., “Principles of Bioseparations Engineering”, World Scientific Publishers,2006.

Reference Books(s) / Web links:

R.O. Jenkins, (Ed.) – Product Recovery In Bioprocess Technology – Biotechnology By Open

1

Learning Series, Butterworth-Heinemann(1992).

J.C. Janson And L. Ryden, (Ed.) – Protein Purification – Principles, High Resolution Methods And

2

Applications, VCH Pub.1989.

3 R.K. Scopes – Protein Purification – Principles And Practice, Narosa Pub.(1994).

BY19202 BIOREACTION ENGINEERING Category L T P C

3 0 0 3

Objectives:

This course will help the students to learn about the design of immobilized enzyme reactors and various

structured and unstructuredmodels.

To gain knowledge about recombinant cell cultivation and the design of reactors for thosecultivation.

UNIT-I METABOLIC STOICHIOMETRYANDENERGETICS 9

Mass and energy balance in biological system – Stoichiometry of cell growth and product formation – Elemental

balances, degrees of reduction of substrate and biomass, available electron balances, yield coefficients of