Page 14 - REC :: M.Tech. BioTech Curriculum and Syllabus - R2019

P. 14

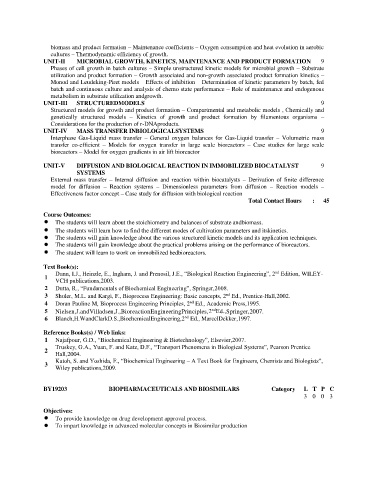

biomass and product formation – Maintenance coefficients – Oxygen consumption and heat evolution in aerobic

cultures – Thermodynamic efficiency of growth.

UNIT-II MICROBIAL GROWTH, KINETICS, MAINTENANCE AND PRODUCT FORMATION 9

Phases of cell growth in batch cultures – Simple unstructured kinetic models for microbial growth – Substrate

utilization and product formation – Growth associated and non-growth associated product formation kinetics –

Monod and Leudeking-Piret models – Effects of inhibition – Determination of kinetic parameters by batch, fed

batch and continuous culture and analysis of chemo state performance – Role of maintenance and endogenous

metabolism in substrate utilization andgrowth.

UNIT-III STRUCTUREDMODELS 9

Structured models for growth and product formation – Compartmental and metabolic models , Chemically and

genetically structured models – Kinetics of growth and product formation by filamentous organisms –

Considerations for the production of r-DNAproducts.

UNIT-IV MASS TRANSFER INBIOLOGICALSYSTEMS 9

Interphase Gas-Liquid mass transfer – General oxygen balances for Gas-Liquid transfer – Volumetric mass

transfer co-efficient – Models for oxygen transfer in large scale bioreactors – Case studies for large scale

bioreactors – Model for oxygen gradients in air lift bioreactor

UNIT-V DIFFUSION AND BIOLOGICAL REACTION IN IMMOBILIZED BIOCATALYST 9

SYSTEMS

External mass transfer – Internal diffusion and reaction within biocatalysts – Derivation of finite difference

model for diffusion – Reaction systems – Dimensionless parameters from diffusion – Reaction models –

Effectiveness factor concept – Case study for diffusion with biological reaction

Total Contact Hours : 45

Course Outcomes:

The students will learn about the stoichiometry and balances of substrate andbiomass.

The students will learn how to find the different modes of cultivation parameters and itskinetics.

The students will gain knowledge about the various structured kinetic models and its application techniques.

The students will gain knowledge about the practical problems arising on the performance of bioreactors.

The student will learn to work on immobilized bedbioreactors.

Text Book(s):

nd

Dunn, I.J., Heinzle, E., Ingham, J. and Prenosil, J.E., “Biological Reaction Engineering”, 2 Edition, WILEY-

1

VCH publications,2003.

2 Dutta, R., “Fundamentals of Biochemical Engineering”, Springer,2008.

3 Shuler, M.L. and Kargi, F., Bioprocess Engineering: Basic concepts, 2 Ed., Prentice-Hall,2002.

nd

nd

4 Doran Pauline M, Bioprocess Engineering Principles, 2 Ed., Academic Press,1995.

nd

5 Nielsen,J.andVilladsen,J.,BioreactionEngineeringPrinciples,2 Ed.,Springer,2007.

nd

6 Blanch,H.WandClarkD.S.,BiochemicalEngineering,2 Ed., MarcelDekker,1997.

Reference Books(s) / Web links:

1 Najafpour, G.D., “Biochemical Engineering & Biotechnology”, Elsevier,2007.

Truskey, G.A., Yuan, F. and Katz, D.F., “Transport Phenomena in Biological Systems”, Pearson Prentice

2

Hall,2004.

Katoh, S. and Yoshida, F., “Biochemical Engineering – A Text Book for Engineers, Chemists and Biologists”,

3

Wiley publications,2009.

BY19203 BIOPHARMACEUTICALS AND BIOSIMILARS Category L T P C

3 0 0 3

Objectives:

To provide knowledge on drug development approval process.

To impart knowledge in advanced molecular concepts in Biosimilar production