Page 331 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 331

Chapter 5 Cold water systems

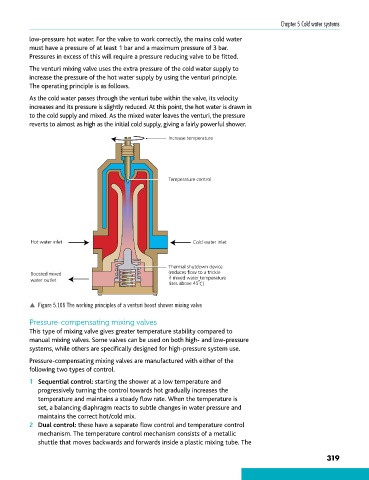

low-pressure hot water. For the valve to work correctly, the mains cold water

must have a pressure of at least 1 bar and a maximum pressure of 3 bar.

Pressures in excess of this will require a pressure reducing valve to be fitted.

The venturi mixing valve uses the extra pressure of the cold water supply to

increase the pressure of the hot water supply by using the venturi principle.

The operating principle is as follows.

As the cold water passes through the venturi tube within the valve, its velocity

increases and its pressure is slightly reduced. At this point, the hot water is drawn in

to the cold supply and mixed. As the mixed water leaves the venturi, the pressure

reverts to almost as high as the initial cold supply, giving a fairly powerful shower.

Increase temperature

Temperature control

Hot water inlet Cold water inlet

Thermal shutdown device

Boosted mixed (reduces flow to a trickle

water outlet if mixed water temperature

º

rises above 45 C)

p Figure 5.106 The working principles of a venturi boost shower mixing valve

Pressure-compensating mixing valves

This type of mixing valve gives greater temperature stability compared to

manual mixing valves. Some valves can be used on both high- and low-pressure

systems, while others are specifically designed for high-pressure system use.

Pressure-compensating mixing valves are manufactured with either of the

following two types of control.

1 Sequential control: starting the shower at a low temperature and

progressively turning the control towards hot gradually increases the

temperature and maintains a steady flow rate. When the temperature is

set, a balancing diaphragm reacts to subtle changes in water pressure and

maintains the correct hot/cold mix.

2 Dual control: these have a separate flow control and temperature control

mechanism. The temperature control mechanism consists of a metallic

shuttle that moves backwards and forwards inside a plastic mixing tube. The

319

9781510416482.indb 319 29/03/19 8:59 PM