Page 336 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 336

The City & Guilds Textbook: Plumbing Book 1

Preparation, planning and positioning of pipes

The installation of cold water systems needs to comply with the Water Supply

(Water Fittings) Regulations and we must always consider the recommendations

of BS EN 806 and BS 8558. The manufacturer’s instructions have to be

followed with regard to the appliances installed and materials used.

The installation procedures will vary depending on the property. For instance,

the methods used on new buildings will differ from those in an occupied

dwelling where the customer’s possessions will need to be taken into account.

Irrespective of the property type, pipework runs need to be planned carefully.

It is advisable to avoid positions where frost and heat could cause a problem,

such as outside walls, in cellars and unheated roof spaces. Wherever possible,

pipework should be positioned out of sight and boxed in where appropriate. It

should be remembered, however, that pipework should not be buried in walls

INDUSTRY TIP or floors unless provision can be made to make it accessible.

Notching and drilling of joists Pipes in suspended timber floors

should be done carefully, Pipes have been installed in timber floors for many years. Notching or drilling

taking care to follow the of joists should not be carried out in joists or rafters 100 mm deep or less.

recommendations mentioned

in Chapter 2, Common Notches should not be too tight for the pipes or creaking and ‘ticking’ noises

processes and techniques, may become a problem as the pipes expand and contract. Pipes in notches

page 121. should be covered with joist clips to prevent excessive movement, and

floorboards should be screwed (not nailed) when they are repositioned.

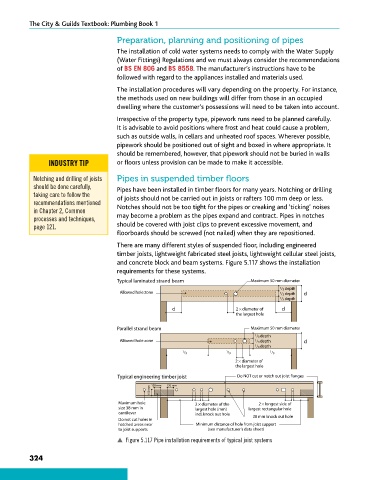

There are many different styles of suspended floor, including engineered

timber joists, lightweight fabricated steel joists, lightweight cellular steel joists,

and concrete block and beam systems. Figure 5.117 shows the installation

requirements for these systems.

Typical laminated strand beam Maximum 50 mm diameter

1 / 3 depth

Allowed hole zone 1 / 3 depth d

1 / 3 depth

d 2 × diameter of d

the largest hole

Parallel strand beam Maximum 50 mm diameter

1 / 3 depth

Allowed hole zone 1 / 3 depth d

1 / 3 depth

1 / 3 1 / 3 1 / 3

2 × diameter of

the largest hole

Typical engineering timber joist Do NOT cut or notch out joist flanges

150 mm 150 mm 150 mm

Maximum hole 2 × diameter of the 2 × longest side of

size 38 mm in largest hole (mm) largest rectangular hole

cantilever incl. knock out hole

Do not cut holes in 38 mm knock out hole

hatched areas near Minimum distance of hole from joist support

to joist supports (see manufacturer's data sheet)

p Figure 5.117 Pipe installation requirements of typical joist systems

324

9781510416482.indb 324 29/03/19 8:59 PM