Page 490 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 490

The City & Guilds Textbook: Plumbing Book 1

Pressure gauge

60

40 80

20 100

0

Type CA

device

Pressure relief valve

and discharge pipework Expansion vessel Cold water supply

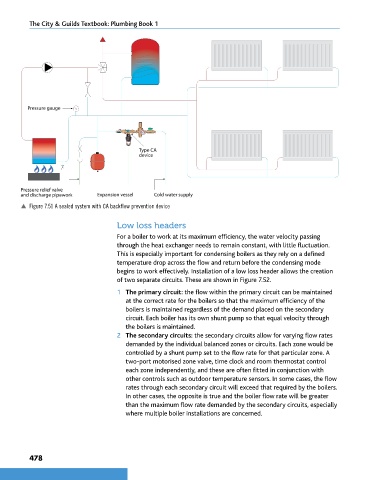

p Figure 7.51 A sealed system with CA backflow prevention device

Low loss headers

For a boiler to work at its maximum efficiency, the water velocity passing

through the heat exchanger needs to remain constant, with little fluctuation.

This is especially important for condensing boilers as they rely on a defined

temperature drop across the flow and return before the condensing mode

begins to work effectively. Installation of a low loss header allows the creation

of two separate circuits. These are shown in Figure 7.52.

1 The primary circuit: the flow within the primary circuit can be maintained

at the correct rate for the boilers so that the maximum efficiency of the

boilers is maintained regardless of the demand placed on the secondary

circuit. Each boiler has its own shunt pump so that equal velocity through

the boilers is maintained.

2 The secondary circuits: the secondary circuits allow for varying flow rates

demanded by the individual balanced zones or circuits. Each zone would be

controlled by a shunt pump set to the flow rate for that particular zone. A

two-port motorised zone valve, time clock and room thermostat control

each zone independently, and these are often fitted in conjunction with

other controls such as outdoor temperature sensors. In some cases, the flow

rates through each secondary circuit will exceed that required by the boilers.

In other cases, the opposite is true and the boiler flow rate will be greater

than the maximum flow rate demanded by the secondary circuits, especially

where multiple boiler installations are concerned.

478

9781510416482.indb 478 29/03/19 9:03 PM