Page 491 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 491

Chapter 7 Central heating systems

Boiler management control

Zone

controller

Zone

controller

Outdoor

sensor

Zone

valves

Shunt

pumps

Primary circuit Secondary circuit

Hot water cylinder

Boiler shunt pumps Low loss

header

Expansion

vessel

Boiler Boiler Boiler

Pressurising unit

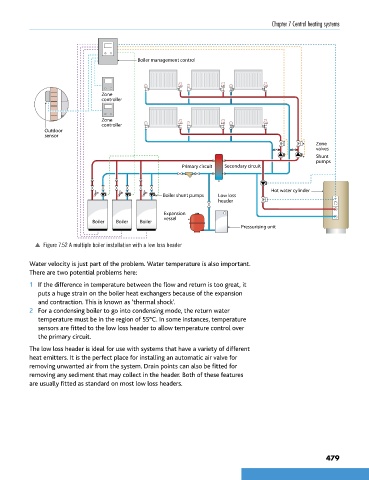

p Figure 7.52 A multiple boiler installation with a low loss header

Water velocity is just part of the problem. Water temperature is also important.

There are two potential problems here:

1 If the difference in temperature between the flow and return is too great, it

puts a huge strain on the boiler heat exchangers because of the expansion

and contraction. This is known as ‘thermal shock’.

2 For a condensing boiler to go into condensing mode, the return water

temperature must be in the region of 55°C. In some instances, temperature

sensors are fitted to the low loss header to allow temperature control over

the primary circuit.

The low loss header is ideal for use with systems that have a variety of different

heat emitters. It is the perfect place for installing an automatic air valve for

removing unwanted air from the system. Drain points can also be fitted for

removing any sediment that may collect in the header. Both of these features

are usually fitted as standard on most low loss headers.

479

9781510416482.indb 479 29/03/19 9:03 PM