Page 61 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 61

Chapter 1 Health and safety practices and systems

● leaking batteries, which contain acid; do not allow a leaking battery to come

into contact with your skin

● not burning spent battery packs as they are liable to explode

● storage restrictions, as set storage temperatures exist for most cordless

power tools.

Procedures for portable electrical tools that fail

inspections

From time to time, electrical tools fail inspections and tests. If this should

happen, on no account must the tool be used. The tool should be labelled as

faulty and taken to the stores or for repair. A record of the fault must be logged

on the maintenance and inspection documents.

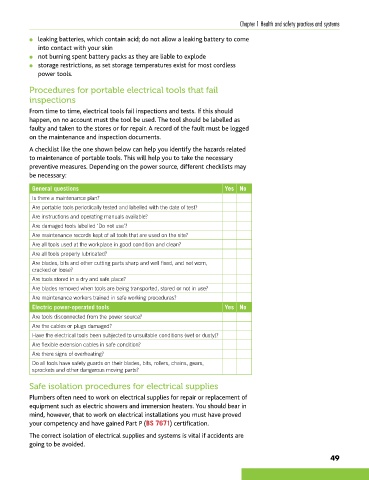

A checklist like the one shown below can help you identify the hazards related

to maintenance of portable tools. This will help you to take the necessary

preventive measures. Depending on the power source, different checklists may

be necessary:

General questions Yes No

Is there a maintenance plan?

Are portable tools periodically tested and labelled with the date of test?

Are instructions and operating manuals available?

Are damaged tools labelled ‘Do not use’?

Are maintenance records kept of all tools that are used on the site?

Are all tools used at the workplace in good condition and clean?

Are all tools properly lubricated?

Are blades, bits and other cutting parts sharp and well fixed, and not worn,

cracked or loose?

Are tools stored in a dry and safe place?

Are blades removed when tools are being transported, stored or not in use?

Are maintenance workers trained in safe working procedures?

Electric power-operated tools Yes No

Are tools disconnected from the power source?

Are the cables or plugs damaged?

Have the electrical tools been subjected to unsuitable conditions (wet or dusty)?

Are flexible extension cables in safe condition?

Are there signs of overheating?

Do all tools have safety guards on their blades, bits, rollers, chains, gears,

sprockets and other dangerous moving parts?

Safe isolation procedures for electrical supplies

Plumbers often need to work on electrical supplies for repair or replacement of

equipment such as electric showers and immersion heaters. You should bear in

mind, however, that to work on electrical installations you must have proved

your competency and have gained Part P (BS 7671) certification.

The correct isolation of electrical supplies and systems is vital if accidents are

going to be avoided.

49

9781510416482.indb 49 29/03/19 8:50 PM