Page 21 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 21

8 Applied Process Design for Chemical and Petrochemical Plants

Saturated steam,

100 p1i9. , E·I C-2

12 lb./hr. \ Distillation tower Product condenser

1

14,275 Btu./hr. 2!.4"dia.x 38 -0• and separator

1•-e• dia.x 10•-o•

r - - - - - - Coolin9 water

I 280.000 Btu./hr.

170 F. 28 !I pm.

180F.

To vacuum equipment

12 lb. of water vapor/hr.

Trace of noncondens·

ables.

13,075 Btu./hr.

Fatty acid

I

I 280MW rF. A.distillate

I lllO lb.ofvapar/hr. I 0.85 Sp. 9r.

c-1 58 lb.of liquid/hr. '-Reflux I 9501b./hr.

Reboiler 527 F. (not required I 134 9al./hr.

,301,400 for design I zero Btu./hr.

feed)

180 F.

Btu./ht

r Crude fatty acid

feed rF.A.liquid Product pump

I 0.85 sp.9r. 0.75 sp.9r. J-4 -A. .

1,000 lb./hr 1 1,768 lb./hr. 225 I" pitch

141 9al./hr. I gpmJ 0.711p.9r.

zero Btu./hr. 475 F. / 501b./hr.

I 0.14 gprn.

180 F. 475 F. 22,600 Btu./hr.

Charge pump Bottoms pump

J-1 J-3

2.35 9prn.

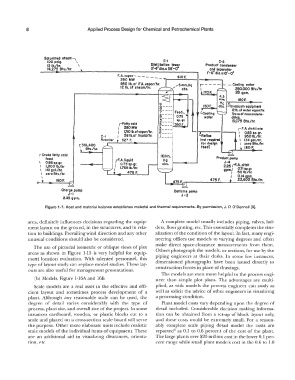

Figure 1-7. Heat and material balance establishes material and thermal requirements. By permission, J.P. O'Donnell [9].

area, definitely influences decisions regarding the equip- A complete model usually includes piping, valves, lad-

ment layout on the ground, in the structures, and in rela- ders, floor grating, etc. This essentially completes the visu-

tion to buildings. Prevailing wind direction and any other alization of the condition of the layout. In fact, many engi-

unusual conditions should also be considered. neering offices use models to varying degrees and often

make direct space-clearance measurements from them.

The use of pictorial isometric or oblique views of plot

areas as shown in Figure 1-15 is very helpful for equip- Others photograph the models, or sections, for use by the

ment location evaluation. With talented personnel, this piping engineers at their desks. In some few instances,

dimensioned photographs have been issued directly to

type of layout study can replace model studies. These lay-

outs are also useful for management presentations. construction forces in place of drawings.

The models are even more helpful Lo the process engi-

(b) Models, Figure l-16A and 16B neer than simple plot plans. The advantages are multi-

Scale models are a real asset in the effective and effi- plied, as with models the process engineer can study as

cient layout and sometimes process development of a well as solicit the advice of other engineers in visualizing

plant. Although any reasonable scale can be used, the a processing condition.

degree of detail varies considerably with the type of Plant model costs vary depending upon the degree of

process, plant site, and overall size of the project. In some detail included. Considerable decision making informa-

instances cardboard, wooden, or plastic blocks cut to a tion can be obtained from a set-up of block layout only,

scale and placed on a cross-section scale board will serve and these costs would be extremely small. For a reason-

the purpose. Other more elaborate units include realistic ably complete scale piping detail model the costs are

scale models of the individual items of equipment. These reported+ as 0.1 to 0.6 percent of the cost of the plant.

are an additional aid in visualizing clearances, orienta- The large plan ts over $20 million cost in the lower 0.1 per-

tion, etc. cent range while small plant models cost in the 0.6 to 1.0