Page 222 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 222

192 Applied Process Design for Chemical and Petrochemical Plants

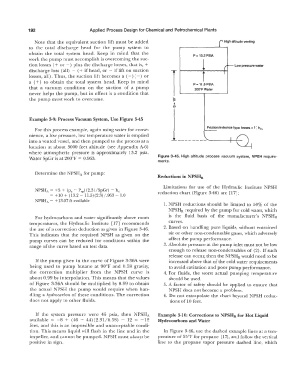

Note that the equivalent suction lift must be added High altitude venting

to the total discharge head for the pump system to

obtain the total system head. Keep in mind that the

work the pump must accomplish is overcoming the suc- P = 13.2 PSIA

tion losses ( + or - ) plus the discharge losses, that is, + l Low pressure water

discharge loss (all) - ( + if head, or - if lift on suction

losses, all). Thus, the suction lift becomes a (-) (-) or r

a ( +) to obtain the total system head. Keep in mind

that a vacuum condition on the suction of a pump P = 11.5 PSIA

200°FWater

never helps the pump, but in effect is a condition that

..

the pump must work to overcome. 0

II

(/)

Example 3-9: Process Vacuwn System, Use Figure 3-45

-

Friction/entrance type losses= 1', hsL

For this process example, again using waler for conve- .

nience, a low pressure, low temperature water is emptied

into a vented vessel, and then pumped lo the process at a

location at about 3000 feet altitude (see Appendix A-6)

where atmospheric pressure is approximately 13.2 psia.

Water SpGr is at 200°F = 0.963. Figure 3-45. High altitude process vacuum system, NPSH require-

ments.

Determine the NPSHA for pump:

Reductions in NPSHR

Limitations for use of the Hydraulic Institute NPSH

NPSHA = +S + (p. -- P"P)(2.31/SpGr) - h,1 reduction chart (Figure 3-46) are [17]:

=+IO+ (13.2 - 11.5)(2.3)/.963 - 1.0

NPSHA = + 13.07 ft available

1. NPSH reductions should be limited to 50% of the

NPSHR required by the pump for cold water, which

For hydrocarbons and water significantly above room is the fluid basis of the manufacturer's NPSHR

temperatures, the Hydraulic Institute [17] recommends curves.

the use of a correction deduction as given in Figure 3-'16. 2. Based on handling pure liquids, without entrained

This indicates that the required NPSH as given on the air or other non-condensable gases, which adversely

pump curves can be reduced for conditions within the affect the pump performance.

range of the curve based on test data. 3. Absolute pressure at the pump inlet must not be low

enough to release non-condensables of (2). If such

release can occur, then the NPSHR would need to be

If the pump given in the curve of Figure 3-36A were increased above that of the cold water requirements

being used to pump butane at 90°F and 0.58 gravity, to avoid cavitation and poor pump performance.

the correction multiplier from the NPSH curve is 4. For fluids, the worst actual pumping temperature

about 0.99 by interpolation. This means that the values should be used.

of Figure 3-36A should be multiplied by 0.99 to obtain 5. A factor of safety should be applied to ensure that

the actual NPSH the pump would require when han- NPSH does not become a problem.

dling a hydrocarbon of these conditions. The correction 6. Do not extrapolate the chart beyond NPSH reduc-

does not apply to other fluids. tions of 10 feet.

If the system pressure were 46 psia, then NPSHA Example 3-10: Corrections to NPSHR for Hot Liquid

available = -8 + (46 - 44) (2.31/0.58) - 12 = -12 Hydrocarbons and Water

feet, and this is an impossible and unacceptable condi-

tion. This means liquid will flash in the line and in the In Figure 3-46, use the dashed example lines at a tem-

impeller, and cannot be pumped. NPSH must always be perature of 55°F for propane [17), and follow the vertical

positive in sign. line to the propane vapor pressure dashed line, which