Page 230 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 230

200 Applied Process Design for Chemical and Petrochemical Plants

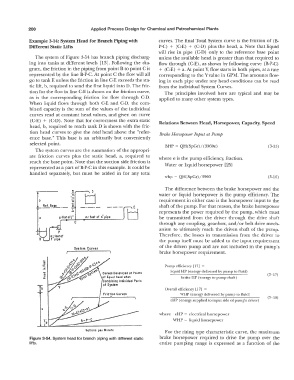

Example 3-14: System Head for Branch Piping with curves. The final Total System curve is the friction of (B-

Different Static Lifts P-C) + (C-E) + (C-D) plus the head, a. Note that liquid

will rise in pipe (C-D) only to the reference base point

The system of Figure 3-54 has branch piping discharg- unless the available head is greater than that required to

ing into tanks at different levels [13]. Following the dia- flow through (C-E), as shown by following curve (B-P-C)

gram, the friction in the piping from point B to point C is + (C-E) + a. At point Y, flow starts in both pipes, at a rate

represented by the line B-P-C. At point C the flow will all corresponding to the Yvalue in GPM. The amounts flow-

go to tank E unless the friction in line C-E exceeds the sta- ing in each pipe under any head conditions can be read

tic lift, b, required to send the first liquid into D. The fric- from the individual System Curves.

tion for the flow in line C-E is shown on the friction curve, The principles involved here are typical and may be

as is the corresponding friction for flow through C'.,-D. applied to many other system types.

When liquid flows through both C-E and C-D, the com-

bined capacity is the sum of the values of the individual

curves read at constant head values, and given on curve

(C-E) + (C-D). Note that for correctness the extra static

head, b, required to reach tank D is shown with the fric- Relations Between Head, Horsepower, Capacity, Speed

tion head curves to give the total head above the "refer- Brake Horsepower Input at Pump

ence base." This base is an arbitrarily but conveniently

selected point.

BHP= QH(SpGr)/(3960e) (3-15)

The system curves are the summation of the appropri-

ate friction curves plus the static head, a, required to where e is the pump efficiency, fraction.

reach the base point. Note that the suction side friction is

represented as a part of B-P-C in this example. It could be \i\Tater or liquid horsepower [25)

handled separately, but must be added in for any total

whp = QH(SpGr)/3960 (3-16)

The difference between the brake horsepower and the

water or liquid horsepower is the pump efficiency. The

requirement in either case is the horsepower input to the

shaft of the pump. For that reason, the brake horsepower

represents the power required by the pump, which must

g·feet of l" m·feet of n"pipe be transmitted from the driver through the drive shaft

c through any coupling, gear-box, and/or belt drive mech-

anism to ultimately reach the driven shaft of the pump.

Therefore, the losses in transmission from the driver to

the pump itself must be added to the input requirement

of the driven pump and are not included in the pump's

System Curves

brake horsepower requirement.

Pump efficiency [ 17) =

liquid HP (energy delivered by pump to fluid)

Curves Developed ot Points (3-17)

of Equol head when brake HP (energy to pump shaft)

Combining Individual Ports

of System

Overall efficiency [ l 7] =

\VI-IP ( energy delivered by pump to fluid)

(3-18)

el-IP (energy supplied to input side of pump's driver)

a

where eHP = electrical horsepower

WHP = liquid horsepower

Gallons per Minute

For the rising L)'Pe characteristic curve, the maximum

Figure 3-54. System head for branch piping with different static brake horsepower required to drive the pump over the

lifts. entire pumping range is expressed as a function of the