Page 229 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 229

Pumping of Liquids 199

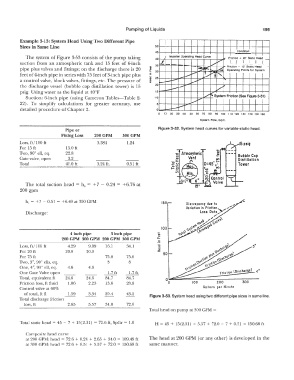

Example 3-13: System Head Using Two Different Pipe

Sizes in Same Line 50 I I I

45 Condition

The system of Figure 3-53 consists of the pump taking 40 , Impeller Operating Head Curve ,,,, .. Friction + 22' Static Head _

suction from an atmospheric tank and 15 feet of 6-inch 35 lL .._ - / t .r 1__, __ 1 .1_

Friction + 15' Static Head

pipe plus valves and fittings; on the discharge there is 20 J 30 - � ,::;.- _..-.::::: Operating Points for System

20 -

feel of 4-inch pipe in series with 75 feet of 3-inch pipe plus .5 �..,..,... t- ... t <, . I

a control valve, block valves, fittings, etc. The pressure of i 25 :...- -- .,....,.. ...

:r

the discharge vessel (bubble cap distillation tower) is 15 15 - � vi"

i.--

psig. Using water as the liquid at 40°F

Suction: 6-inch pipe (using Cameron Tables-Table 2- 110 ......- t> I'" System Friction (See Figure 3-51)

22). To simplify calculations for greater accuracy, use 5 � .,....,.. I I I I I I I i

�

detailed procedure of Chapter 2. 0 - !

0 10 20 30 40 50 60 70 80 90 100 110 120 130 uo 150 160

System Flow, Gpm.

Pipe or Figure 3-52. System head curves for variable static head.

Fitting Loss 200 GPM 300 GPM

Loss, ft/100 ft 0.584 1.24 15 psi;

For 15 ft 15.0 fl

Two, 900 ell, eq. 22.8 A tmos!)heric Bubble Cop

Gate valve, open __1,L Vent Distillation

Total 41.0 ft 0.24 ft. 0.51 ft Tower

The total suction head = h, = +7 - 0.24 = +6.76 at

200 gpm

h, = +7 ·- 0.51 = +6.49 at 300 GPM 150 Discrepancy due lo ....,

Variation in Friction, .,.,-'

Discharge: Lou Doto.,�

/

.... " ,it'

1:,

�<t°',"' ,_,...,\

�.... 'ti:,

100 x C:,'\ � ':-_ .,._\ � °''t\CIC)j

4 inch pipe 3 inch pipe :: -<,o.'°'

200 GPM 300 GPM 200 GPM 300 GPM ....

c:

..

Loss, ft/ l OC ft 4.29 9.09 16.1 34.1 "O 3"

0

For 20 ft 20.0 20.0 :I: 50

For 75 fl 75.0 75.0

Two, 3", 90° ells, eq. 8 8

One, 4", 90° ell, eq. 4.6 4.6

\Oischorgel .;"

friclion

One Gate Valve open L. 7 fl 1.7 ft o���==::::::::::::===�

Total, equivalent ft 24.6 24.6 84.7 84.7

Friction loss, ft fluid 1.06 2.23 i3.6 28.8 0 100 200 300

Control valve al 60% Gallons per Minute

of total, ft fl 1.59 3.34 20.4 43.2 Figure 3-53. System head using two different pipe sizes in same line.

Total discharge friction

loss, ft 2.65 5.57 34.0 72.0

Total head on pump at 300 GPM =

Total static head= 45 - 7 + 15(2.31) = 72.6 ft, SpGr = 1.0 H = 45 + 15(2.31) + 5.57 + 72.0 - 7 + 0.51 = 150.68 ft

Composite head curve

at 200 GPM: head = 72.6 + 0.24 + 2.65 + 34.0 = 109.49 ft The head at 200 GPM (or any other) is developed in the

at 300 GPM: head = 72.6 + 0.51 + 5.57 + 72.0 = 150.68 ft same manner.