Page 291 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 291

Mechanical Separations 261

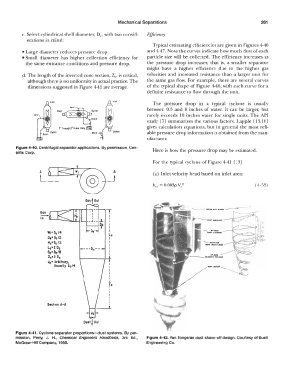

c. Select cylindrical shell diameter, D with two consid- Efficiency

0

erations in mind:

Typical estimating efficiencies are given in Figures 4-46

• Large diameter reduces pressure drop and 4-47. Note the curves indicate how much dust of each

• Small diameter has higher collection efficiency for particle size will be collected. The efficiency increases as

the same entrance conditions and pressure drop. the pressure drop increases; that is, a smaller separator

might have a higher efficiency due to the higher gas

d. The length of the inverted cone section, Zc, is critical, velocities and increased resistance than a larger unit for

although there is no uniformity in actual practice. The the same gas flow. For example, there are several curves

dimensions suggested in Figure 4-41 are average. of the typical shape of Figure 4-46, with each curve for a

definite resistance to flow through the unit.

lnltl lnltl The pressure drop in a typical cyclone is usually

i rarely exceeds 10 inches water for single units. The API

\nit! between 0.5 and 8 inches of water. It can be larger, but

study [7] summarizes the various factors. Lapp le [ 13, 16]

gives calculation equations, but in general the most reli-

Oulltl able pressure drop information is obtained from the man-

ufacturer.

Figure 4-40. Centrifugal separator applications. By permission, Cen- Here is how the pressure drop may be estimated.

trlflx Corp.

For the typical cyclone of Figure 4-41 [13]

A A (a) Inlet velocity head based on inlet area:

L _ _j

hui = 0.003p v( 2 (4-53)

- I I

Gas

In

I

__ .J. __ ..L

Sc I

�-D,-..JT I I -.. aT-l'AH

W1= Dc/4 Le DUIT CHAHNll

D,• Dc/2 I

He= Dc/2 I I ---- IHIIT ro•

oun lADIN GASU

Lc•2 De ---De-- I

Sc• Dc/8 I I

Zc•2 De 1-------J-t

Jc• Arbitrary, I

Usually Dc/4 I

I

I

I

I

I

fc

I

I

I

I

I

Section A-A I I

--1..

Jc

Dust J Out

Figure 4-41. Cyclone separator proportions-dust systems. By per-

mission, Perry, J. H., Chemical Engineers Handbook, 3rd Ed., Figure 4-42. Van Tongeran dust shave-off design. Courtesy of Buell

McGraw-Hill Company, 1950. Engineering Co.