Page 34 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 34

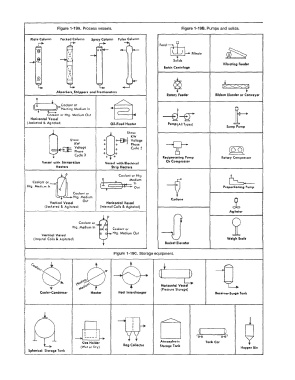

Figure 1-19A. Process vessels. Figure 1-198. Pumps and solids.

Plate Column Packed Column Spray Column Pulse Column

Feed �

� Filtrate

Solids

� Vibrating Feeder

Batch Centrifuge

[:< '><'. ·:< >:]

Absorbers, Stripf"rs and Fractionators t

Rotary Feeder Ribbon Blender or Conveyor

� ' ;)- � ::::. �

;'.;,d;om lo

Coolant or Htg. Medium Out

Horizontal Vessel

(Jacketed & Ag)ated) Oil-Fired Heater Pump (All Types)

Sump Pump

Show:

KW

Show: o o-fl=} Voltage

KW o o Phase

Voltage o O Cycle 5

O

Phase 0 0

Cycle 3 0 0 Reciprocating Pump Rotary Comprenor

Vesse! with Immersion Vessel wit.h Electrical Or Compreuor

Heaters Strip Heaters

u

Medium

Coolant o, * Coolant or Htg. �

Htg. Medium In Coolant or )��ut --1 Proportioning Pump

Out

Vertical Vessel Htg. Medium Horizontal Vessel Cyclone i

(Jacketed & Agitated) (Internal Coils & Agitated) Agitator

Coolant or -D 2

Htg. Medium In

Coolant or

Htg. Medium Out

Vertical Venel

(Internal Coils & Agitated) Weigh Scale

Bucket Elevator

! Figure 1-19C. Storage equipment.

������ - ���������������� -.- ���������

........ ����������-!

0010,.,, � + ,,,0 � -fl

l , 1 1 : .

\'l � e3: Horizontal Vessel �

I ,.. (Pressure Storage)

I Cooler-Condenser Heater Heat Interchanger Receiver-Surge Tank

r

£WO a D

Gas Holder Atmospheric 'ere Tank Car G-e I

(Wet or Dry) Bag Collector Storage Tank Hopper Bin

Spherical �torage Tank

������-����������-'-���������'--�������--'L...���������--''--����� ....