Page 370 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 370

338 Applied Process Design for Chemical and Petrochemical Plants

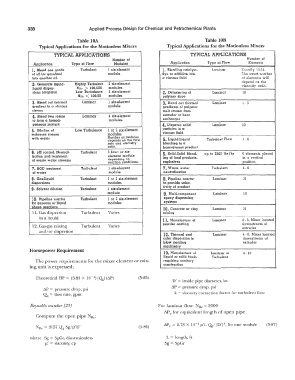

Table IOA Table IOB

Typical Applications for the Motionless Mixers Typical Applications for the Motionless Mixers

TYPICAL APPLICATIONS TYPICAL APPLICATIONS

Number of Number of

Application Type of Flow Modules Application Type of Flow Elements

1. Blend one grade Turbulent 1 six-element 1. Blending catalyst. Laminar Usually 10-14.

of oil (or gasoline) module dye or additive into The exact number

Into another oil. a viscous fluid of elements will

depend on the

2. Generate liquid- Highly Turbulent 2 six-element viscosity ratio.

liquid disper- NRe > 100.000 modules

sions (droplets) Low Turbulence 3 six-element 2. De!ustering of Laminar 10

NRe < 100,00 modules polymer dope

3, Blend out thermal Laminar 1 six-element 3. Blend out thermal Laminar 4-6

gradient in a viscous module gradients of polymer

stream melt stream from

4, Blend two resins Laminar 4 six-element extruder or heat

to form a homoq- modules exchanger

geneous mixture 4. Disperse solid Laminar 10

5, Dilution of Low Turbulence l or 2 six-element particles in a

molasses stream modules viscous fluid

with water Number of modules 5. Liquid-Liquid Turbulent Flow 4-6

depends on the flow

rate and viscosity blending to a

ratio. homogenous product

6, pH control. Neutral- Turbulent 1 four- or six- 6. Solid-Solid Blend- up to 2500 lbs/hr 6 elements placed

izalion and treatment element module ing of food products, in a vertical

of waste water streams depending on explosives position.

reaction conditions.

7, BOD treabnent Turbulent 1 six-element 7. Waste water Turbulent 4-6

of water module neutralization

8. Gas-liquid Turbulent 1 or 2 six-element 8. Pipeline reactor Laminar 10

dispersions modules lo provide selec-

tivity of product

9, Solvent dilution Turbulent l six-element

module 9. Multi-component Laminar 10

l Q. Pipeline reactor Turbulent I or 2 six-element epoxy dispensing

for gaseous or liquid modules systems

phase reactions 10. Concrete or clay Laminar 10

11. Gas dispersion Turbulent Varies mixing

in a liquid

11. Manufacture of Laminar 4 - 6. Mixer located

powder coating downstream ol

12. Gas-gas mixing Turbulent Varies extruder

and/ or dispersion

12. Thermal and Laminar 4 - 6. Mixer located

color dispersion in downstream ol

blow molding extruder

machinery

Horsepower Requirement

13. Manufacture ol Laminar or 4-10

liquid or solid foods Turbulent

The power requirements for the mixer element or mix- requiring sanitary

construction

ing unit is expressed:

Theoretical HP= (5.83 X 10- 4) (Qg) (t.P) (5-85)

D' = inside pipe diameter, in.

t.P = pressure drop, psi

t.P = pressure drop, psi

Qg = flow rate, gpm k = viscosity correction factor for turbulent flow

Reynolds number [25} For laminar flow: NRc < 2000

L'1P for equivalent length of open pipe

0

Compute the open pipe NRe:

NRc = 3157 Qg Sg/µ'D' (5-86) t.P 0 = 2.73 X 10- 4 µ'L Qg/(D')1. for one module (5-87)

where Sg = SpGr, dimensionless L = length, ft

µ' = viscosity, cp Sg = SpGr