Page 367 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 367

Mixing of Liquids 335

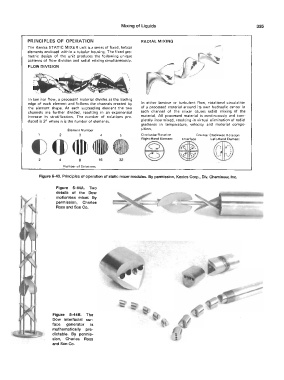

PRINCIPLES OF OPERATION RADIAL MIXING

The Kenics STATIC MIXER unit is a series of fixed, helical

elements enclosed within a tubular housing. The fixed geo-

metric design of the unit produces the following unique

patterns of flow division and radial mixing simultaneously.

FLOW DIVISION

In laminar flow, a processed material divides at the leading

edge of each element and follows the channels created by In either laminar or turbulent flow, rotational circulation

the element shape. At each succeeding element the two of a processed material around its own hydraulic center in

channels are further divided, resulting in an exponential each channel of the mixer causes radial mixing of the

increase in stratification. The number of striations pro- material. All processed material is continuously and com-

duced is 2n where n is the number of elements. pletely intermixed, resulting in virtual elimination of radial

gradients in temperature, velocity and material compo-

sition.

Element Number

2 3 4 5 Clockwise Rotation Counter Clockwise Rotation

Right-Hand Element Interface Left-Hand Element

ES, .. .

2 4 8 16 32 '

Number of Striations

Figure 5-43. Principles of operation of static mixer modules. By pennission, Kenics Corp., Div. Chemineer, Inc.

Figure 5-44A. Two

details of the Dow

motionless mixer. By

permission, Charles

Ross and Son Co.

Figure 5-448. The

Dow interfacial sur-

face generator is

mathematically pre-

dictable. By permis-

sion, Charles Ross

and Son Co.