Page 377 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 377

Ejectors and Mechanical Vacuum Systems 345

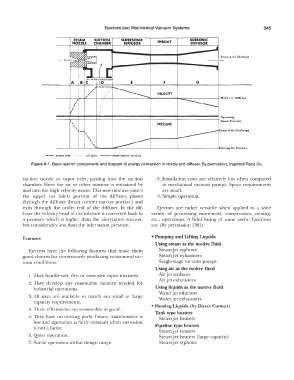

I STEAM SUCTION SUPERSONIC SUBSONIC

NOZZLE CHAMBER DIFFUSOR THROAT DIFFUSOR

Steam & Air Diuhorge

A B E F G

VELOCITY

----+--,.1--r---t----:�-t--------=""j,-------,._=:--------t Moch I= 1000 Ip,

I

I

I

---+--+-+-- ..... ---+---------+------+--------� Operating

Steam Pressure

' PRESSURE

' \

Steam & Air Discharge

\

' '

'

' \

steam only - ···· air only -- steam and air mixture

Figure 6-1. Basic ejector components and diagram of energy conversion in nozzle and diffuser. By permission, Ingersoll-Rand Co.

suction nozzle or vapor inlet, passing into the suction 8. Installation costs are relatively low when compared

chamber. Here the air or other mixture is entrained by to mechanical vacuum pumps. Space requirements

and into the high velocity steam. This new mixture enters are small.

the upper (or inlet) portion of the diffuser, passes 9. Simple operation.

through the diffuser throat (center narrow portion) and

exits through the outlet end of the diffuser. In the dif- Ejectors are rather versatile when applied to a wide

fuser the velocity head of the mixture is converted back to variety of processing movement, compression, mixing,

a pressure which is higher than the air-mixture suction, etc., operations. A brief listing of some useful functions

but considerably less than the inlet steam pressure. are (By permission [30]):

Features • Pumping and Lifting Liquids

Using steam as the motive fluid

Ejectors have the following features that make them Steam jet syphons

good choices for continuously producing economical vac- Steam jet exhausters

uum conditions: Single-stage vacuum pumps

Using air as the motive fluid

1. They handle wet, dry, or corrosive vapor mixtures. Air jet syphons

Air jet exhausters

2. They develop any reasonable vacuum needed for

industrial operations. Using liquids as the motive fluid

Water jet eductors

3. AJl sizes are available to match any small or large Water jet exhausters

capacity requirements.

• Heating Liquids (by Direct Contact)

4. Their efficiencies are reasonable to good.

Tank type heaters

5. They have no moving parts, hence, maintenance is Stearn jet healers

low and operation is fairly constant when corrosion

is not z factor. Pipeline type heaters

Steam jet heaters

6. Quiet operation. Steam jet heaters (large capacity)

7. Stable operation within design range. Steam jet syphons