Page 380 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 380

348 Applied Process Design for Chemical and Petrochemical Plants

zero load or shutoff pressure, Reference [18] indicates the

approximate values for evacuation pressures (lowest):

Stage No. in System Lowest Absolute Pressure, mm Hg abs

Single 50

Two 4 to 10

Three 0.8 to 1.5

Suction Four 0.1 to 0.2

Five 0.01 to 0.02

Six 0.001 to 0.003

Single Stage Figure 6-10 is a summary of operating pressure ranges

for a variety of processes and vapor mixtures.

Table 6-1 and Table 6-3 gives the usual industrial appli-

cation ranges for ejector stages.

Figures 6-llA, B, and C indicate the capacity of various

ejector-condenser combinations for variable suction pres-

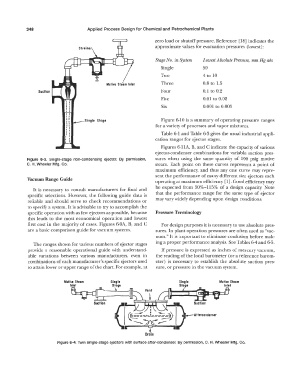

Figure 6-3. Single-stage non-condensing ejector. By permission, sures when using the same quantity of 100 psig motive

C. H. Wheeler Mfg. Co. steam. Each point on these curves represents a point of

maximum efficiency, and thus any one curve may repre-

sent the performance of many different size ejectors each

Vacuum Range Guide

operating at maximum efficiency [1]. Good efficiency may

be expected from 50%-115% of a design capacity. Note

It is necessary to consult manufacturers for final and

specific selections. However, the following guide data is that the performance range for the same type of ejector

reliable and should serve to check recommendations or may vary widely depending upon design conditions.

to specify a system. It is advisable to try to accomplish the

specific operation with as few ejectors as possible, because Pressure Terminology

this leads to the most economical operation and lowest

first cost in the majority of cases. Figures 6-9A, B, and C For design purposes it is necessary to use absolute pres-

are a basic comparison guide for vacuum systems. sures. In plant operation pressures are often used as "vac-

uum." It is important to eliminate confusion before mak-

ing a proper performance analysis. See Tables 6-4 and 6-5.

The ranges shown for various numbers of ejector stages

provide a reasonable operational guide with understand- If pressure is expressed as inches of mercury vacuum,

able variations between various manufacturers, even in the reading of the local barometer ( or a reference barom-

combinations of each manufacturer's specific ejectors used eter) is necessary to establish the absolute suction pres-

to attain lower or upper range of the chart. For example, at sure, or pressure in the vacuum system.

Motive Steam Sino le Sin,;ile Motive Steam

' � --s_,_o_ e Sto,;ie Inlet

__

--��-- Aflercondenser

Suction

(c---:! __

?)

' ( D ) I

+.

Dram

Figure 6-4. Twin single-stage ejectors with surface after-condenser. By permission, C. H. Wheeler Mfg. Co.