Page 381 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 381

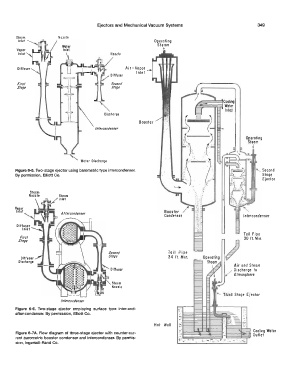

Ejectors and Mechanical Vacuum Systems 349

Steam Nozzle

Operating

•

�:;:: � I 1:1�e" Steam

"'"iJf7}

Diffuser .:J [ Air-Vapor

Firs/ J Inlet

Stage

Cooling

Wot er

lnleJ

Discharge

Intercondenser

Operating

Steam

..

Water Discharge

Figure 6-5. Two-stage ejector using barometric type intercondenser. , Second

By permission, Elliott Co. Stage

Ejector

Steam

Nozzle Steam

Inlet

VaP.or

Inlet Booster /

Condenser

Toil Pipe

First 30 ft. Min.

Stage

Toil Pipe

34 ft. Min.

Air and Steam

Diffuser / Discharge to

It' Atmosphere

Steam

Nozzle

/nlercondenser

Figure 6-6. "Two-stage ejector employing surface type inter-and-

after'-condenser. By permission, Elliott Co.

..

....

Hot Well

·. Cooling Water

•.

Figure 6-7A. Flow diagram of three-stage ejector with counter-cur- Outlet

rent barometric booster condenser and intercondenser. By permis-

sion, Ingersoll-Rand Co.