Page 448 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 448

414 Applied Process Design for Chemical and Petrochemical Plants

pre-assembly

screw pressure

gauge

holddown __

rupture disc -

base :"

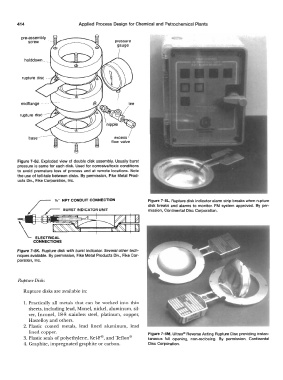

Figure 7-SJ. Exploded view of double disk assembly. Usually burst

pressure is same for each disk. Used for corrosive/toxic conditions

to avoid premature loss of process and at remote locations. Note

the use of tell-tale between disks. By permission, Fike Metal Prod-

ucts Div., Fike Corporation, Inc.

r- W' NPT CONDUIT CONNECTION Figure 7-SL. Rupture disk indicator alarm strip breaks when rupture

disk breaks and alarms to monitor. FM system approved. By per-

�:ff � ---- - 1 �

/ mission, Continental Disc Corporation.

� iURSTINDICATORUNIT

...............

_._._..__P_

!

".:: ELECTRICAL

CONNECTIONS

Figure 7-SK. Rupture disk with burst indicator. Several other tech-

niques available. By permission, Fike Metal Products Div., Fike Cor-

poration, Inc.

Rupture Disks

Rupture disks are available in:

1. Practically all metals that can be worked into thin

sheets, including lead, Mone), nickel, aluminum, sil-

ver, Inconel, 18--8 stainless steel, platinum, copper,

Hastelloy and others.

2. Plastic coated metals, lead lined aluminum, lead

lined copper. Figure 7-SM. Ultrex® Reverse Acting Rupture Disc providing instan-

3. Plastic seals of polyethylene, Kel-F®, and Teflon® taneous full opening, non-reclosing. By permission, Continental

4. Graphite, impregnated graphite or carbon. Disc Corporation.