Page 452 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 452

418 Applied Process Design for Chemical and Petrochemical Plants

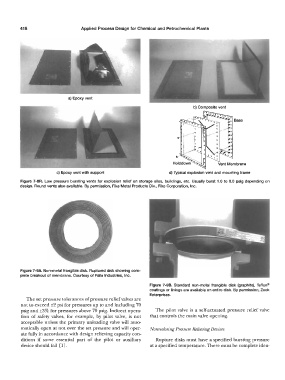

a) Epoxy vent

b) Composite vent

c) Epoxy vent with support d) Typical explosion vent and mounting frame

Figure 7-SR. Low pressure bursting vents for explosion relief on storage silos, buildings, etc. Usually burst 1.0 to 8.0 psig depending on

design. Round vents also available. By permission, Fike Metal Products Div., Fike Corporation, Inc.

Figure 7-9A. Non-metal frangible disk. Ruptured disk showing com-

plete breakout of membrane. Courtesy of Falls Industries, Inc.

Figure 7-98. Standard non-metal frangible disk (graphite), Teflon®

coatings or linings are available on entire disk. By permission, Zook

Enterprises.

The set pressure tolerances of pressure relief valves are

not to exceed ±2 psi for pressures up to and including 70

psig and ±3% for pressures above 70 psig. Indirect opera- The pilot valve is a self-actuated pressure relief valve

tion of safety valves, for example, by pilot valve, is not that controls the main valve opening.

acceptable unless the primary unloading valve will auto-

matically open at not over the set pressure and will oper- Nonreclosing Pressure Relieving Devices

ate fully in accordance with design relieving capacity con-

ditions if some essential part of the pilot or auxiliary Rupture disks must have a specified bursting pressure

device should fail [ 1]. at a specified temperature. There must be complete iden-