Page 449 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 449

Process Safety and Pressure-Relieving Devices 415

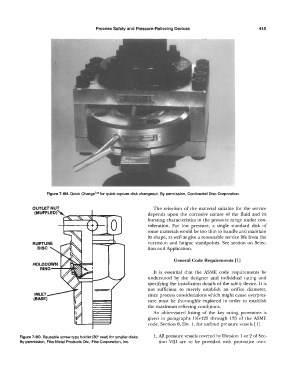

Figure 7-SN. Quick Change™ for quick rupture disk changeout. By permission, Continental Disc Corporation.

OUTLET NUT The selection of the material suitable for the service

(MUFFLED)''--- ��� -:::,,,,-

.... depends upon the corrosive nature of the fluid and its

bursting characteristics in the pressure range under con-

sideration. For low pressure, a single standard disk of

some materials would be too thin to handle and maintain

its shape, as well as give a reasonable service life from the

corrosion and fatigue standpoints. See section on Selec-

tion and Application.

General Code Requirements [I]

HOLD DOWN

RING-+-,11�

It is essential that the ASME code requirements be

understood by the designer and individual rating and

specifying the installation details of the safety device. It is

not sufficient to merely establish an orifice diameter,

INLET since process considerations which might cause overpres-

(BASE)

sure must be thoroughly explored in order to establish

the maximum relieving conditions.

An abbreviated listing of the key rating provisions is

given in paragraphs UG-125 through 135 of the ASME

code, Section 8, Div. 1, for unfired pressure vessels [ 1].

Figure 7-80. Reusable screw type holder (30° seat) for smaller disks. 1. All pressure vessels covered by Division 1 or 2 of Sec-

By permission, Fike Metal Products Div., Fike Corporation, Inc. tion VIII are to be provided with protective over-